A Guide to: Filtration

By: Brent Nakano

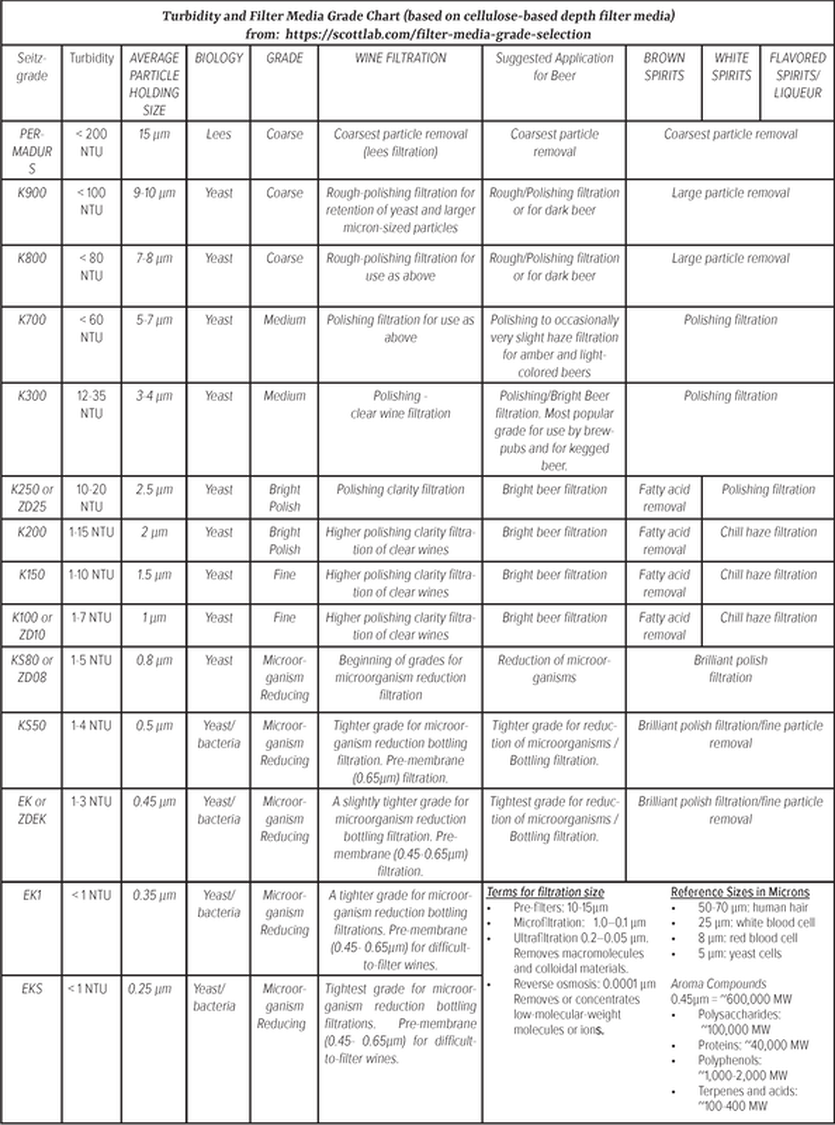

When discussing production methodologies from the sales side of the alcoholic beverage industry, filtration is often mentioned, but it is referred to as a homogenous process that magically removes some elements from the product to make it better (or worse, depending on who you talk to). Filtration is not homogenous, however, but highly technical. It operates at the molecular level, and is based on significant amounts of academic research. Any conversation about filtration’s impact on flavor should be rooted in the benefits and drawbacks of specific filtration technologies, not filtration as a whole.