Rum

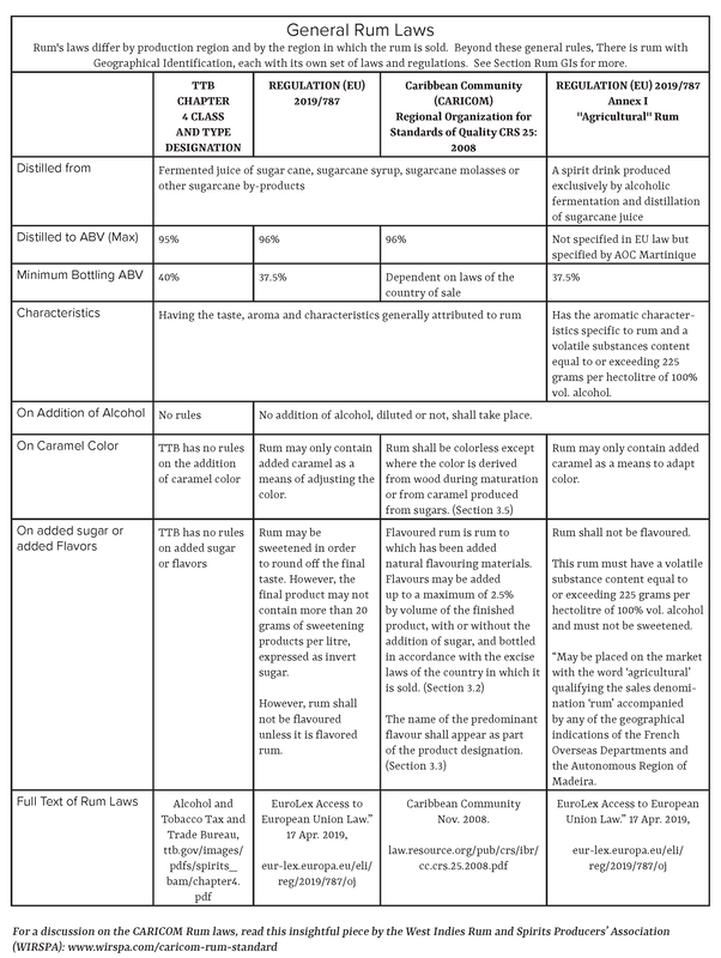

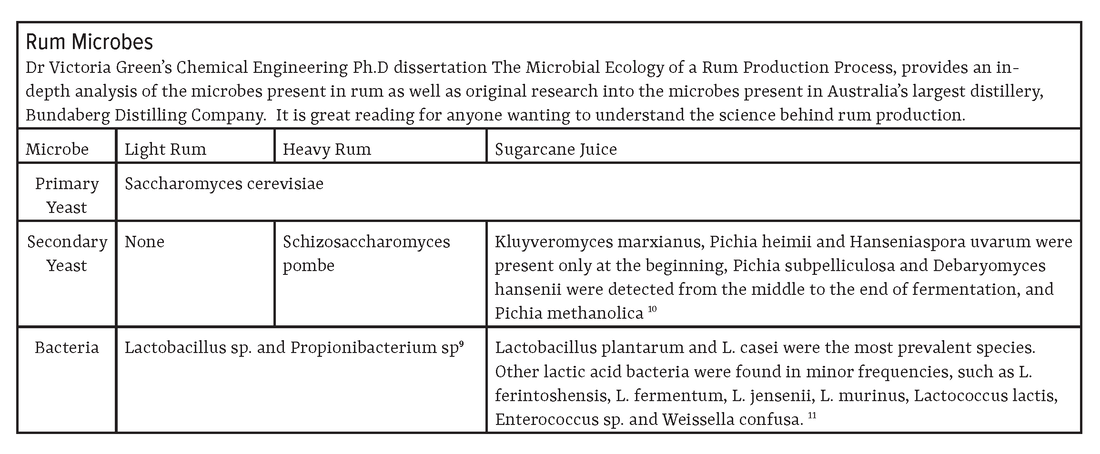

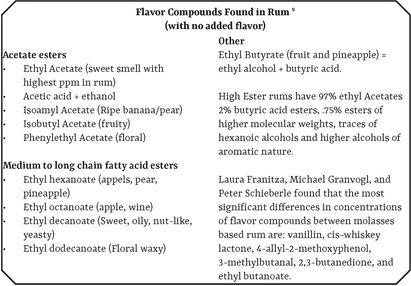

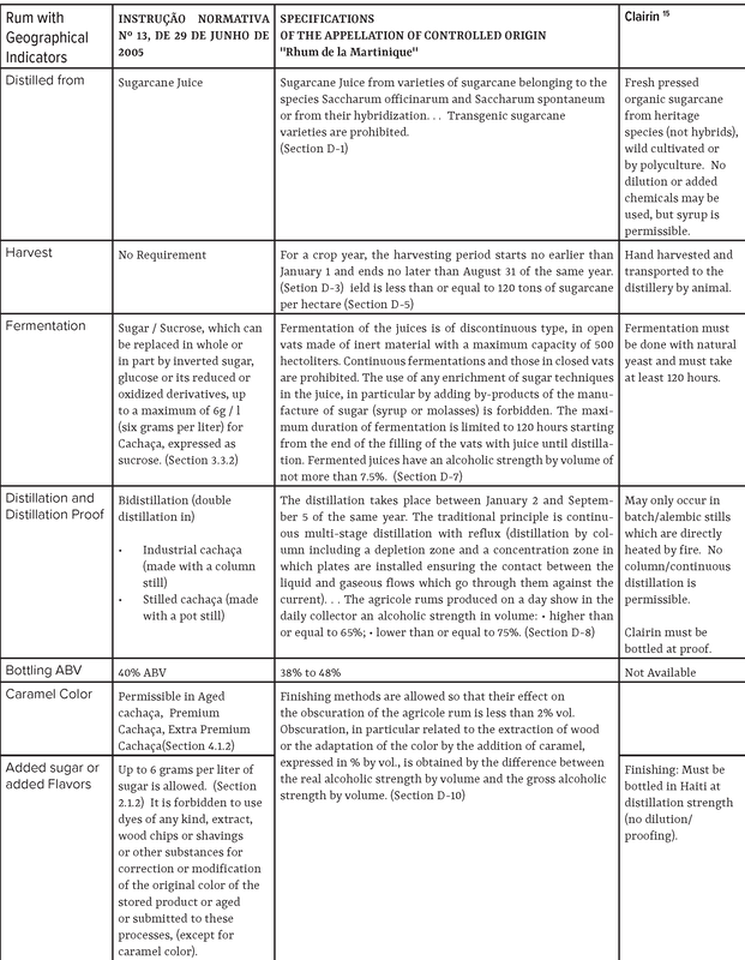

Rum is a more complex category than many of the rules would lead one to believe. Sugarcane distillates come in various iterations. In the United States, they are often all lumped into one category: Rum. However, the category is much more complex, since there are multiple geographical indications defining ingredients and production methodologies in order to preserve a traditional method. The Alcohol and Tobacco Tax and Trade Bureau (TTB’s) definition of rum is lax, which allows for companies to label sugarcane distillate with artificial flavors and lots of added sugar as “rum.” Ultimately, many of the legacy rum producers in the Caribbean have been calling for increased transparency throughout the manufacturing process.