Beer Available in Hawaii

A Guide to Oak Barrels

|

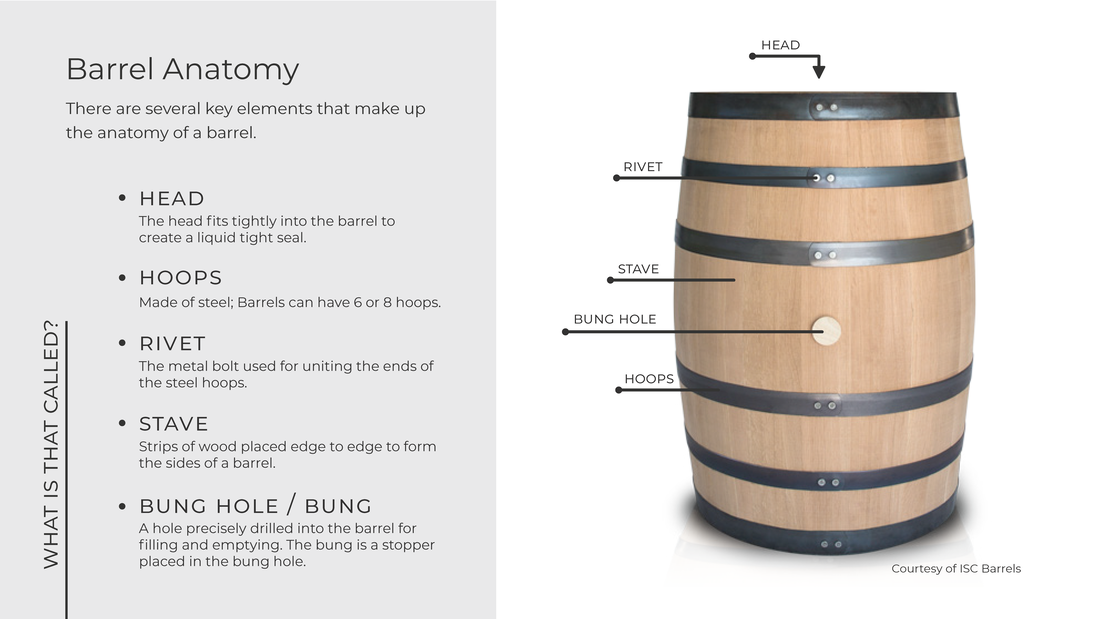

Barrels, which evolved from wooden buckets, were once the primary method of transporting liquids. However, with the evolution of material science, they are now primarily used to do the following:

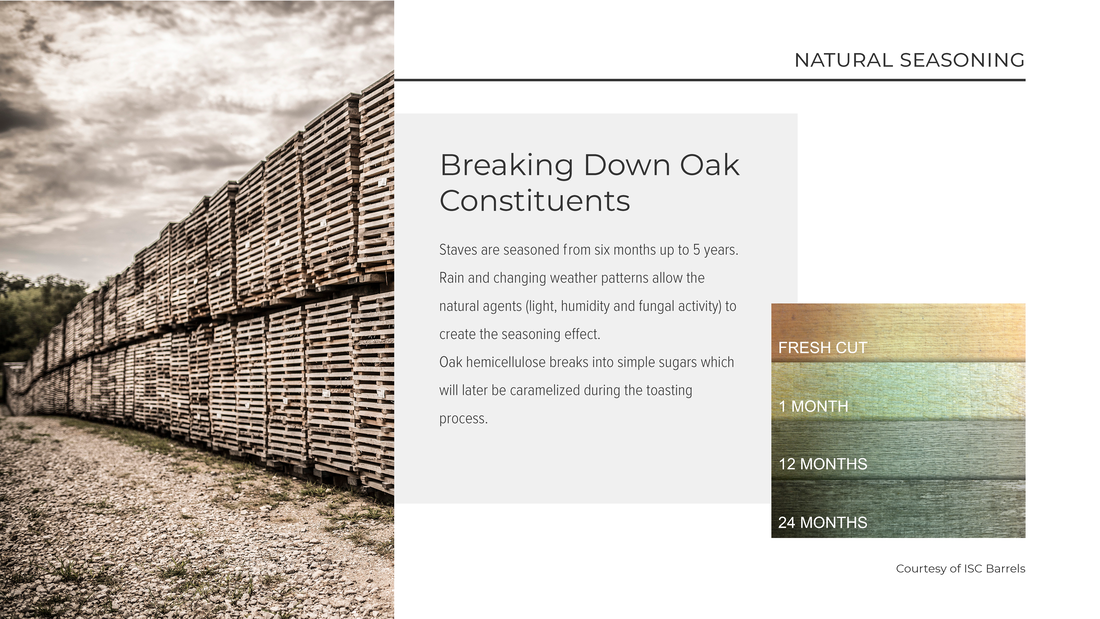

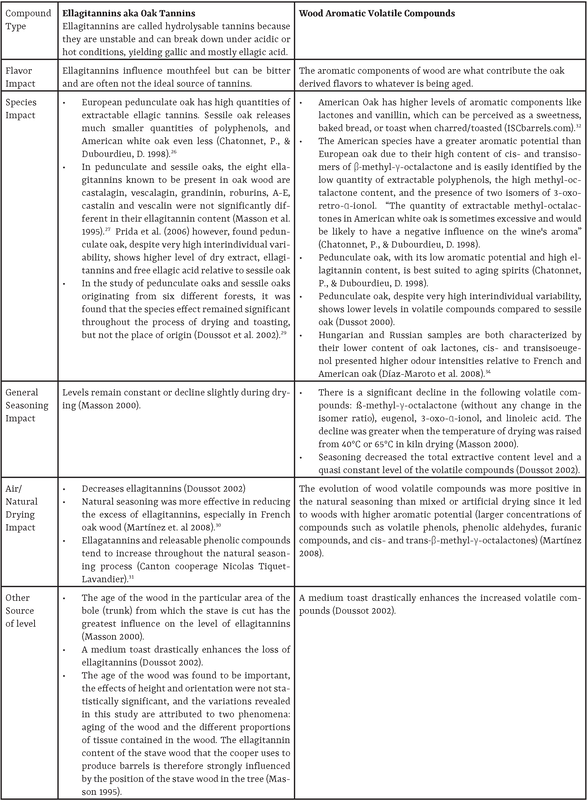

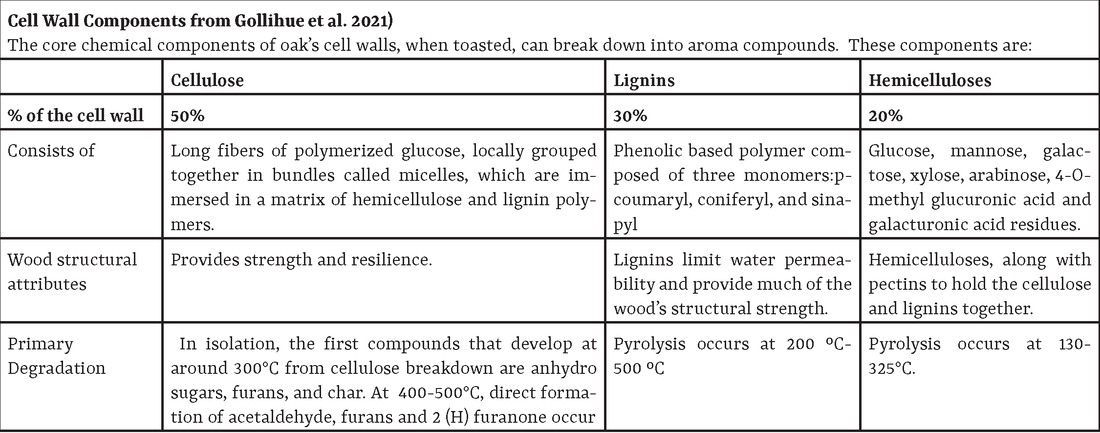

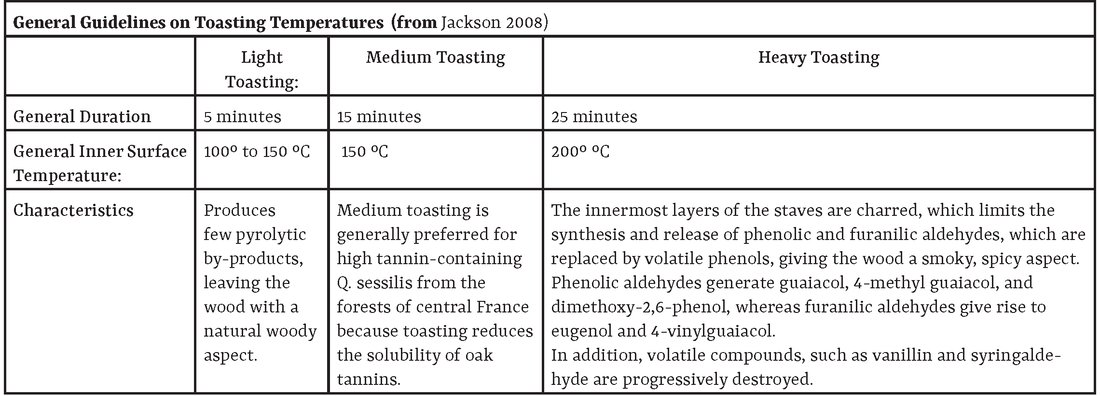

Not every oak barrel contributes the same characteristics or has the same influence. Differences in wood used to make the barrel and the production process, including differences in the type of treatment to prepare the wood, what is being aged in the barrel, under what conditions and for how long, have significant impacts on the chemical reactions that contribute aroma compounds. |

We have referenced a multitude of studies to better understand the components of oak; however, there are two comprehensive articles that stood out, and to which we have made numerous references. Each is more detailed from a chemistry perspective than the information we are providing, but we highly recommend reading them. They are:

For Wine: Jackson, R. S. (2008). Wine Science: Principles and Applications. Netherlands: Elsevier Science. www.elsevier.com/books/wine-science/jackson/978-0-12-816118-0 For Spirits and in particular Whiskey: Gollihue, J., Pook, V. G., and DeBolt, S. (2021) Sources of variation in bourbon whiskey barrels: a review. J. Inst. Brew., 127: 210– 223. doi.org/10.1002/jib.660 |