A Guide to:

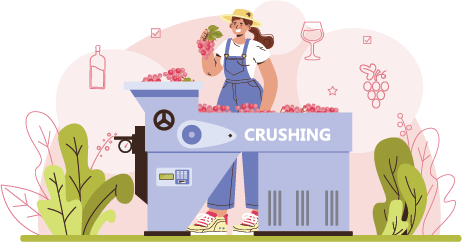

Wine Prefermentation Processes

By: Brent Nakano

After the grapes are picked and transported to the winery, the process begins.

Great insight for this article was obtained from our favorite book on wine:

Wine Science by Ronald Jackson available at www.elsevier.com/books/wine-science/jackson/978-0-12-816118-0

Great insight for this article was obtained from our favorite book on wine:

Wine Science by Ronald Jackson available at www.elsevier.com/books/wine-science/jackson/978-0-12-816118-0