Post Fermentation Flavor Adjustments

By; Brent Nakano

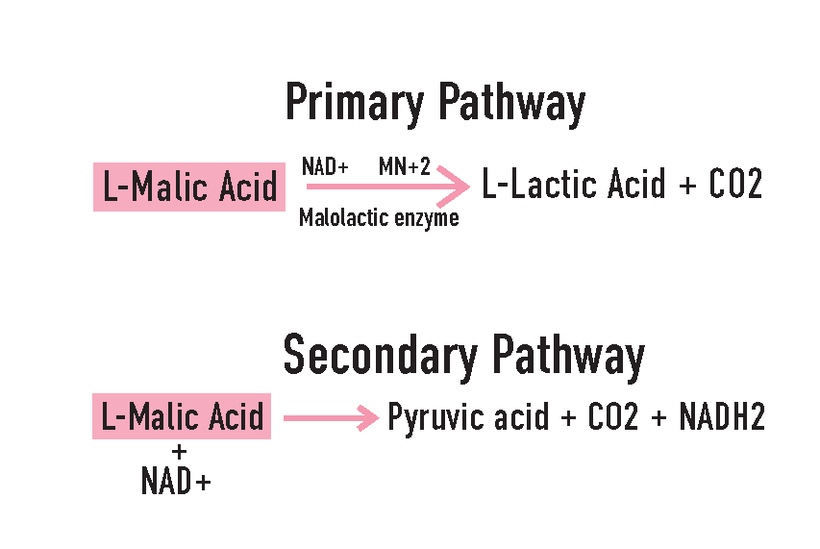

Once fermentation is complete adjustments like Malolactic Fermentation, Sur Life Maturation, and Blending have a profound impact on the final wine. Each has a multitude of options that a winemaker can choose from to influence the wine.