|

Address

4350 Waialo Rd. Port Allen Marina Center Port Allen, HI 96705 Hours of Operation Monday-Friday: 11p-9p Happy Hour: 3p-6p Phone Number (808) 355-0006 https://kauaiislandbrewing.com/ |

Kauai Island Beer is a legacy in Hawaii. The craft brewery was originally founded in 1998 (making it the second oldest brewery in Hawaii) under the name Waimea Brewing Company. Though its name and location have changed in 2012, the core team of Bret Larson, Janice Larson and Dave Curry (brewmaster) has remained. Hawaii Beverage Guide had the opportunity to talk story with (Bret) Larson and Curry to learn more about the brewery.

Founding Story

It all started in 1996 with a little five-barrel DME Brewing System at the Waimea Plantation Cottages. “As with many start-up breweries, it took us a couple years to get things rolling. It wasn’t until '98 that we officially opened our doors and then we ran successfully for 13 years afterwards.” Said Larson. “That’s not to say we didn’t run into some crazy situations along the way but then again, who wouldn’t, trying to run the “Worlds Westernmost Brewpub” from one of Kauai’s westernmost towns. In addition to supplying the general population with handcraft beer, we were also fortunate enough to also be the food and beverage provider for the Waimea Plantation Cottages. But all along the way, we were trying to educate the west side of Kauai everything about Hawaiian craft beer,” he added.

Larson continued, “This experience was quite an adventure all in itself because at that time most people were drinking [macro brewery brands], but when they'd come into our place we had all of this craft beer, [and] they’d always ask what we have that was similar to Coors or Budweiser. We [carried on this way] for years and years; it was a testament to our determination. We never gave up. We just really enjoyed being on the west side in Waimea and teaching locals about craft beer. We just kept rolling as Waimea Brewing Company. Fast forward 13 years, [and] our lease was up. We wanted to stay in our current location, but our landlord had other ideas for the space.

[As we began our search] for another location, my wife, Janice, found an old warehouse in Port Allen across from the tour boat companies, thinking it would be perfect for a Brewpub. So after 13 years, we ended up moving out of Waimea [and] right up the street (about 8 miles away to be more precise). [We] built out the old warehouse, which used to be the old Rainbow Paint and Bait Supply, and rebranded ourselves. [However, we still] carried [over] some of [our] original labels like Captain Cooks IPA, Wai’ale’ale Golden Ale, NaPali Pale ale, Cane Fire Red and Alakai Stout, [while adding] a bunch of original beers that Dave created like The Fonz IPAaaa, AuRye IPA, a lillkoi ale and kalo beer (a huge local favorite) made from taro root. Kauai Island Brewing completed the rebrand, buildout in 2010.

Just before the global pandemic, we finished up a 1500 sq ft Lanai with a solar lid that provides about 1/3 of our electrical needs. We try to be as environmentally sustainable as possible with a low carbon foot print. We source as much of our food products as we can from local farmers and growers. We look for sustainable fish and all of our beef is from local grass fed cows.

After many years working with the old DME Brewing System, we purchased a brand new 10 barrel JVNW brewing system and upgraded our Fermenter vessels and Brite tanks to 10 barrels. We've been running Kauai Island Brewing Company ever since so technically speaking, next to Kona Brewing Company who opened in 1994, we’re one of the oldest running “OG” Breweries in Hawaii.

It all started in 1996 with a little five-barrel DME Brewing System at the Waimea Plantation Cottages. “As with many start-up breweries, it took us a couple years to get things rolling. It wasn’t until '98 that we officially opened our doors and then we ran successfully for 13 years afterwards.” Said Larson. “That’s not to say we didn’t run into some crazy situations along the way but then again, who wouldn’t, trying to run the “Worlds Westernmost Brewpub” from one of Kauai’s westernmost towns. In addition to supplying the general population with handcraft beer, we were also fortunate enough to also be the food and beverage provider for the Waimea Plantation Cottages. But all along the way, we were trying to educate the west side of Kauai everything about Hawaiian craft beer,” he added.

Larson continued, “This experience was quite an adventure all in itself because at that time most people were drinking [macro brewery brands], but when they'd come into our place we had all of this craft beer, [and] they’d always ask what we have that was similar to Coors or Budweiser. We [carried on this way] for years and years; it was a testament to our determination. We never gave up. We just really enjoyed being on the west side in Waimea and teaching locals about craft beer. We just kept rolling as Waimea Brewing Company. Fast forward 13 years, [and] our lease was up. We wanted to stay in our current location, but our landlord had other ideas for the space.

[As we began our search] for another location, my wife, Janice, found an old warehouse in Port Allen across from the tour boat companies, thinking it would be perfect for a Brewpub. So after 13 years, we ended up moving out of Waimea [and] right up the street (about 8 miles away to be more precise). [We] built out the old warehouse, which used to be the old Rainbow Paint and Bait Supply, and rebranded ourselves. [However, we still] carried [over] some of [our] original labels like Captain Cooks IPA, Wai’ale’ale Golden Ale, NaPali Pale ale, Cane Fire Red and Alakai Stout, [while adding] a bunch of original beers that Dave created like The Fonz IPAaaa, AuRye IPA, a lillkoi ale and kalo beer (a huge local favorite) made from taro root. Kauai Island Brewing completed the rebrand, buildout in 2010.

Just before the global pandemic, we finished up a 1500 sq ft Lanai with a solar lid that provides about 1/3 of our electrical needs. We try to be as environmentally sustainable as possible with a low carbon foot print. We source as much of our food products as we can from local farmers and growers. We look for sustainable fish and all of our beef is from local grass fed cows.

After many years working with the old DME Brewing System, we purchased a brand new 10 barrel JVNW brewing system and upgraded our Fermenter vessels and Brite tanks to 10 barrels. We've been running Kauai Island Brewing Company ever since so technically speaking, next to Kona Brewing Company who opened in 1994, we’re one of the oldest running “OG” Breweries in Hawaii.

The development of Kauai’s craft brewing industry

“I've seen a lot of our regular customers switch from macro-style beers to the micro-style beers in a big way. It's really fun to look around and see a lot of locals who we knew were more Coors and Coors Light drinkers come in and grab a Wai’ale’ale Ale, Leilani Light, or Lilikoi Ale which are much lighter ales not lager beer. The IPAs are another one that really surprised us. A lot of our local clientele are really grabbing onto the IPAs. We've started brewing a light pilsner, and we've had a couple of people come in and order one like a Corona. Our bartender will encourage the local customers to sample our pilsner, and then sure enough, we end up with an instant convert! Some people have asked if we do any sours. That's another area that we're exploring. We haven't really got into the “hazy craze.” I know a lot of people like them, but we really haven't gotten there yet. It seems like in some respects, the beer scene here lags several years from the mainland.”

“I've seen a lot of our regular customers switch from macro-style beers to the micro-style beers in a big way. It's really fun to look around and see a lot of locals who we knew were more Coors and Coors Light drinkers come in and grab a Wai’ale’ale Ale, Leilani Light, or Lilikoi Ale which are much lighter ales not lager beer. The IPAs are another one that really surprised us. A lot of our local clientele are really grabbing onto the IPAs. We've started brewing a light pilsner, and we've had a couple of people come in and order one like a Corona. Our bartender will encourage the local customers to sample our pilsner, and then sure enough, we end up with an instant convert! Some people have asked if we do any sours. That's another area that we're exploring. We haven't really got into the “hazy craze.” I know a lot of people like them, but we really haven't gotten there yet. It seems like in some respects, the beer scene here lags several years from the mainland.”

Ingredients

-

Malts

-

Hops

-

Water

-

Yeast

<

>

Broken Boundary Brewery’s tagline, and the general approach to brewing is: "Respect for tradition, authentic innovation." “We respect the traditional styles [of beer] because, over hundreds of years, people perfected the combination of the ingredients they had available. There's a lot of knowledge that comes from the traditional styles and the brewers that made them. We try to learn from those styles and then come up with new and innovative directions to move in; new beers to make.” Said Chris.

When asked what the Broken Boundary Brewery’s tagline looks like in practice, Chris explained, “When we approach a traditional style, we start by tasting as many commercial examples of that style that we can get our hands on. Next, we talk about what we like and what we don’t like in those samples, then we study how the beers (that we liked) are brewed, looking to understand how those breweries produce the flavors we like, and how we can accomplish similar results with our equipment.”

Belgian beers are a great example. The Belgians take their mashing very seriously. They know they can produce different flavor profiles by stepping their mash through a variety of temperatures. So we study the different temperatures they’re employing, understand which enzymes are promoted at those temperatures and how they affect the flavor of the final product, then try to affect those temperature steps in our process with our equipment in order to produce a quality beer that is directly inspired by the traditional process used in Belgium.”

Chris continued to explain, “When looking at new beer trends, we look at the science behind them to understand how these flavors are being produced in the beer. Right now, this is especially notable in the production of Hazy IPA’s, which is a relatively new style with a limited amount of traditional knowledge available to study. As craft beers in the U.S. have been pursuing ever greater hop flavor in their beers, the researchers have been keeping pace. We know more now about what makes hop flavor than ever before. When we look at this research at Broken Boundary Brewery, we are inspired to apply this knowledge in our own way. From trying to get unusual aromas from a pale ale without dry hopping, to choosing yeast strains that are specifically able to unlock the aroma potential of specific hops, we look to contemporary scientific research to guide us.”

“As for Innovation, beer is a complicated beverage. You’ve got at least two agricultural products in the barley malt and in the hops that are subject to variation in strain, climate, and farming technique. You’ve got water chemistry that varies from location to location, and you’ve got a living, single-celled organism in yeast that, in their trillions, turns a sweet barley tea into beer. On top of that, various yeast strains go about their molecular alchemy in stunningly different ways. We’re drastically oversimplifying here, but you can see the permutations are enormous. Beer styles evolved in a world where brewers were largely limited to the local ingredients available to them. In contemporary brewing, we have access to a dizzying variety of hops, malts, and yeast strains, and the ability to match most water profiles from around the world through a knowledge of water chemistry that didn’t exist when traditional beer styles evolved.” Said Chris.

When asked what the Broken Boundary Brewery’s tagline looks like in practice, Chris explained, “When we approach a traditional style, we start by tasting as many commercial examples of that style that we can get our hands on. Next, we talk about what we like and what we don’t like in those samples, then we study how the beers (that we liked) are brewed, looking to understand how those breweries produce the flavors we like, and how we can accomplish similar results with our equipment.”

Belgian beers are a great example. The Belgians take their mashing very seriously. They know they can produce different flavor profiles by stepping their mash through a variety of temperatures. So we study the different temperatures they’re employing, understand which enzymes are promoted at those temperatures and how they affect the flavor of the final product, then try to affect those temperature steps in our process with our equipment in order to produce a quality beer that is directly inspired by the traditional process used in Belgium.”

Chris continued to explain, “When looking at new beer trends, we look at the science behind them to understand how these flavors are being produced in the beer. Right now, this is especially notable in the production of Hazy IPA’s, which is a relatively new style with a limited amount of traditional knowledge available to study. As craft beers in the U.S. have been pursuing ever greater hop flavor in their beers, the researchers have been keeping pace. We know more now about what makes hop flavor than ever before. When we look at this research at Broken Boundary Brewery, we are inspired to apply this knowledge in our own way. From trying to get unusual aromas from a pale ale without dry hopping, to choosing yeast strains that are specifically able to unlock the aroma potential of specific hops, we look to contemporary scientific research to guide us.”

“As for Innovation, beer is a complicated beverage. You’ve got at least two agricultural products in the barley malt and in the hops that are subject to variation in strain, climate, and farming technique. You’ve got water chemistry that varies from location to location, and you’ve got a living, single-celled organism in yeast that, in their trillions, turns a sweet barley tea into beer. On top of that, various yeast strains go about their molecular alchemy in stunningly different ways. We’re drastically oversimplifying here, but you can see the permutations are enormous. Beer styles evolved in a world where brewers were largely limited to the local ingredients available to them. In contemporary brewing, we have access to a dizzying variety of hops, malts, and yeast strains, and the ability to match most water profiles from around the world through a knowledge of water chemistry that didn’t exist when traditional beer styles evolved.” Said Chris.

Chris, a self described beer geek, is currently the sole recipe developer, though he does bounce ideas off his assistant brewer at Broken Beer Brewery, and is looking to eventually expand the creative team. His process starts with a lot of reading and participating in as many brewing conferences as he can. “If I'm interested in something, then I’ll read a lot about it. Being a creative-minded person, if something really intrigues me, I start thinking, ‘Well maybe I can use it this way, this way, or this way,’ and some of those turn out to be good ideas.”

He then discusses new ideas with the “other beer geeks” on the island. “Eulerson’s [Pajimula], at Beer Lab, knowledge of yeast is really amazing. Josh at Hana Koa is a great beer geek. Tim from Village is also a great resource; I like bouncing ideas off of him. Actually, I call [Village Bottleshop] the library. When I want to study a new style, I go to Village Bottleshop and ask Tim to help me find as many examples of the style as possible.” After collecting sample beers to use as reference, test batches are performed on a homebrew system. This cross referencing provides an understanding of the different flavors produced by variations in ingredients and processes.

However, in the development process, everything doesn’t go smoothly. “Sometimes, I make a beer, and there’s some aspect of the flavor that I just don’t like. These ‘misses’ are opportunities. At the moment, it’s disappointing that the beer won’t go into production right away and that it won’t contribute to the income of the business, but as a brewer and as a creative, these moments are valuable because they are the moments when I can clearly see how to improve my processes. These undesirable flavors are targets that I can focus my research on. I just have to learn what they are, how I produced them, and then fit that knowledge into the process to avoid producing them in the next batch. The great thing is that this increased understanding of the process doesn’t just improve the beer I’m working on, it informs the process for making every other beer. The knowledge gained has compounded benefits to the production process as a whole.” Explained Chris.

Like in the culinary world, recipe development is also predicated on equipment. Chris gave the following analogy, “It’s like being in a kitchen, if you don't have a blender, there [will be] some [dishs] that [will] be very hard to [prepare]. No matter who you are, your equipment is going to provide limitations as well as capabilities.” He then provided the following example, “We do a Kolsch fairly regularly. It's one of our best-selling beers. We do as much traditional processing as we can. I've never been to Cologne, but I've talked to several people who are from Germany or have spent time there who say that we're getting pretty close to the traditional examples brewed there. But there are some things that they do over there that we cannot [do here], like decorate the mash, which is where you take a portion of your mash out and boil it and then put it back in to raise the temperature to another step. We don't have a slurry pump and we don't have that secondary kettle. So instead we research: "Why do they decoction mash? What are the chemicals that they're trying to get out of it? What are the reactions they're trying to do?" And then we try to approximate those flavors the best we can, given our equipment and our knowledge. You know the old saying, there's more than one way to skin a cat? That's how we approach everything. We look at lots of different ways that we can produce those flavors and sometimes we can take an amalgamation of different techniques to get where we're going.”

He then discusses new ideas with the “other beer geeks” on the island. “Eulerson’s [Pajimula], at Beer Lab, knowledge of yeast is really amazing. Josh at Hana Koa is a great beer geek. Tim from Village is also a great resource; I like bouncing ideas off of him. Actually, I call [Village Bottleshop] the library. When I want to study a new style, I go to Village Bottleshop and ask Tim to help me find as many examples of the style as possible.” After collecting sample beers to use as reference, test batches are performed on a homebrew system. This cross referencing provides an understanding of the different flavors produced by variations in ingredients and processes.

However, in the development process, everything doesn’t go smoothly. “Sometimes, I make a beer, and there’s some aspect of the flavor that I just don’t like. These ‘misses’ are opportunities. At the moment, it’s disappointing that the beer won’t go into production right away and that it won’t contribute to the income of the business, but as a brewer and as a creative, these moments are valuable because they are the moments when I can clearly see how to improve my processes. These undesirable flavors are targets that I can focus my research on. I just have to learn what they are, how I produced them, and then fit that knowledge into the process to avoid producing them in the next batch. The great thing is that this increased understanding of the process doesn’t just improve the beer I’m working on, it informs the process for making every other beer. The knowledge gained has compounded benefits to the production process as a whole.” Explained Chris.

Like in the culinary world, recipe development is also predicated on equipment. Chris gave the following analogy, “It’s like being in a kitchen, if you don't have a blender, there [will be] some [dishs] that [will] be very hard to [prepare]. No matter who you are, your equipment is going to provide limitations as well as capabilities.” He then provided the following example, “We do a Kolsch fairly regularly. It's one of our best-selling beers. We do as much traditional processing as we can. I've never been to Cologne, but I've talked to several people who are from Germany or have spent time there who say that we're getting pretty close to the traditional examples brewed there. But there are some things that they do over there that we cannot [do here], like decorate the mash, which is where you take a portion of your mash out and boil it and then put it back in to raise the temperature to another step. We don't have a slurry pump and we don't have that secondary kettle. So instead we research: "Why do they decoction mash? What are the chemicals that they're trying to get out of it? What are the reactions they're trying to do?" And then we try to approximate those flavors the best we can, given our equipment and our knowledge. You know the old saying, there's more than one way to skin a cat? That's how we approach everything. We look at lots of different ways that we can produce those flavors and sometimes we can take an amalgamation of different techniques to get where we're going.”

The three biggest factors of brewing in Hawaii that shape the kind of beer brewed at Broken Boundary Brewing are: 1) availability of ingredients and equipment, 2) The impact of visitors in an economy dominated by tourism and hospitality, and 3) The tropical climate.

Chris elaborated, “Brewing ingredients are more expensive in Hawai’i, and there’s no way around it. Our raw goods prices are 100-150% more than breweries on the mainland pay, at least. To combat this, we tend to bring in larger quantities of ingredients, and a smaller variety. So the game for me is to try and find ingredients with the most versatility so that my products are distinct and provide a greater range of flavor experiences for our guests. The same goes for equipment. While breweries in California can drive their pick-up trucks to a winery and get a few barrels for aging at $25 a piece, the same barrels are going to cost me $400-$500 dollars. So If I’m going to do barrel aging, I’ve got to do more planning to make sure the ROI is going to be there. The same goes for any large piece of equipment.

In our business plan, we recognize an inherent difference between our customers that live in town, and those who are visiting. We know that our immediate community-- the people who work on our block, the students at HCC, and the people who live and work in Kalihi, are hugely important to our success, and so we pay attention to the beers they like to drink and make sure they’re available. At the same time, we pay attention to national trends in the beer industry so that we can anticipate the tastes and preferences of our customers who are visiting the island. In most cases, there is a large disparity between the beers our neighbors like and those the visitors like. [To address this], we craft our production model to ensure that we’re accommodating as many preferences as we can.

Finally, Hawaii’s amazing weather plays a factor in which beers sell well. While I love an Imperial Stout, rarely do I grab a six pack of 10% dark beer before I head to a BBQ. We know that we need to keep in mind the active, outdoor lifestyles of all our customers and ensure that we’re producing products that compliment those lifestyles. Additionally, there is an intriguing side to Hawaii’s climate that informs how we make our beer, and that’s the availability of fresh agricultural products that aren’t available to most breweries on the mainland. We’ve begun to experiment with some of these ingredients, like lilikoi, starfruit, and ginger, and we plan to expand our incorporation of tropical flavors as we grow. The beautiful thing is that in doing so, we’re supporting our local farmers and supporting greater food independence for the whole state.”

Chris elaborated, “Brewing ingredients are more expensive in Hawai’i, and there’s no way around it. Our raw goods prices are 100-150% more than breweries on the mainland pay, at least. To combat this, we tend to bring in larger quantities of ingredients, and a smaller variety. So the game for me is to try and find ingredients with the most versatility so that my products are distinct and provide a greater range of flavor experiences for our guests. The same goes for equipment. While breweries in California can drive their pick-up trucks to a winery and get a few barrels for aging at $25 a piece, the same barrels are going to cost me $400-$500 dollars. So If I’m going to do barrel aging, I’ve got to do more planning to make sure the ROI is going to be there. The same goes for any large piece of equipment.

In our business plan, we recognize an inherent difference between our customers that live in town, and those who are visiting. We know that our immediate community-- the people who work on our block, the students at HCC, and the people who live and work in Kalihi, are hugely important to our success, and so we pay attention to the beers they like to drink and make sure they’re available. At the same time, we pay attention to national trends in the beer industry so that we can anticipate the tastes and preferences of our customers who are visiting the island. In most cases, there is a large disparity between the beers our neighbors like and those the visitors like. [To address this], we craft our production model to ensure that we’re accommodating as many preferences as we can.

Finally, Hawaii’s amazing weather plays a factor in which beers sell well. While I love an Imperial Stout, rarely do I grab a six pack of 10% dark beer before I head to a BBQ. We know that we need to keep in mind the active, outdoor lifestyles of all our customers and ensure that we’re producing products that compliment those lifestyles. Additionally, there is an intriguing side to Hawaii’s climate that informs how we make our beer, and that’s the availability of fresh agricultural products that aren’t available to most breweries on the mainland. We’ve begun to experiment with some of these ingredients, like lilikoi, starfruit, and ginger, and we plan to expand our incorporation of tropical flavors as we grow. The beautiful thing is that in doing so, we’re supporting our local farmers and supporting greater food independence for the whole state.”

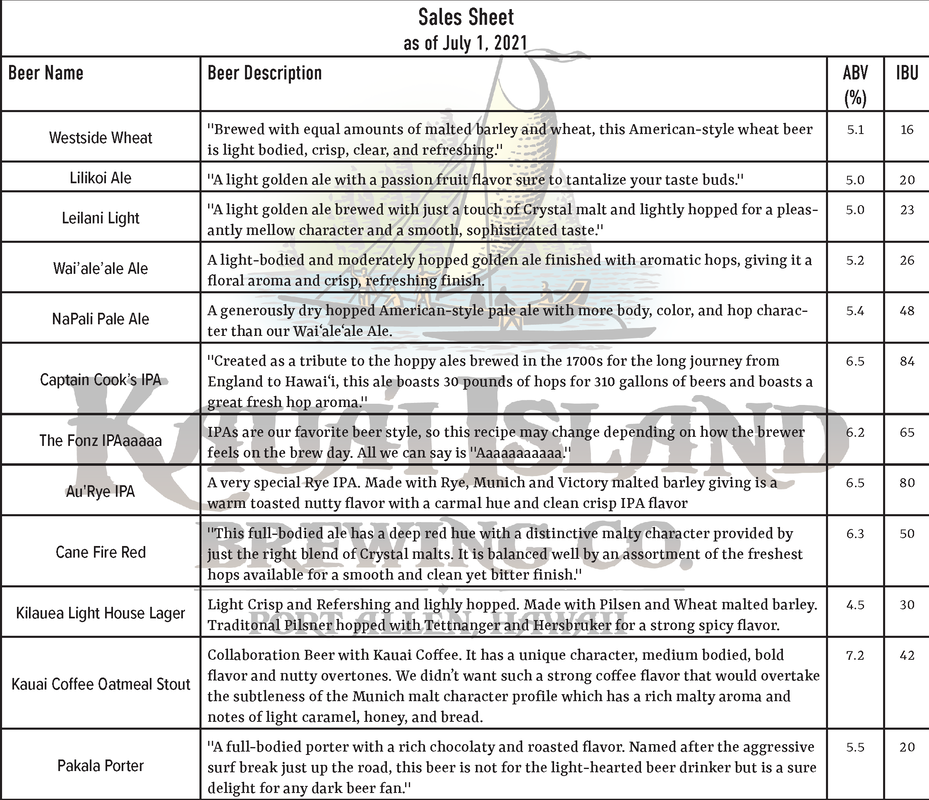

The Beer

Our IPA’s are very popular. We try to have a beer style for every customers taste. So we’ll typically have our Captain Cooks IPA, or the Fonz IPA, our Cane Fire Red, Wai’ale’ale Golden Ale, NaPali Pale Ale, Alakai Stout or Pakala Porter. We also like to have a lighter ale line up such as our Lelani or Lilikoi which has a bit of passion fruit added. We’ve recently started to keep a regular Pilsner on tap and have just ventured in the word of Seltzers.

We’ll typically have about 12-14 beers on tap. We’ve got some rotational beers such as our Belgian Dubbel and Kalo (Taro). We just recently made a collaboration beer with Kauai Coffee using some of their estate reserve Mundo Novo and produced a wonderful Coffee Oatmeal Breakfast Stout. I have to say, it was quite popular with all of our guests.

We’ll typically have about 12-14 beers on tap. We’ve got some rotational beers such as our Belgian Dubbel and Kalo (Taro). We just recently made a collaboration beer with Kauai Coffee using some of their estate reserve Mundo Novo and produced a wonderful Coffee Oatmeal Breakfast Stout. I have to say, it was quite popular with all of our guests.

Up next

“I really like the barrel-aged beers that people bring out here. A lot of travelers travel with beer and they seek out the brewpubs and [their respective brewer] to have a beer with him; it’s a nice way to become acquainted with their beer. Barrel ageing is something that I definitely want to look into next. It's certainly much higher on my list than sours.”

|

Available Quantities

5.2 Gal (20L) 7.75 Gal (1/4bbl) 13.2 Gal (50L) *Cans coming soon |

Also Available

Coasters: $2.00 per sleeve (175per sleeve) Logo Glassware: $1.75 each or $42.00 per case Captain Cooks IPA Mustard: $3.00 each or $30.00 per case |

For prices contact

Kauai Island Brewing Company 4350 Waialo Rd, Eleele, HI 96705 808-355-0006 www.kauaiislandbrewing.com |