The Science of Tequila

By: Brent Nakano

In the production of a distilled spirit, the first question that needs to be answered is: What is being fermented? The answer, when it comes to alcoholic fermentation, lies on a molecular level, because it is a molecular process which requires glucose or sucrose to undergo alcoholic fermentation by Saccharomyces cerevisiae. However, in many fermentations, a raw material needs to be transformed into glucose or sucrose first.

Metl in the Náhuatl language, or maguey (de Sahagún et al., 1970), is more recently known as “agave,” a term used by botanist Carlos Linneo in 1793, who derived the word from the Greek word “agavus,” which means admirable and illustrious. For this guide, we referenced The Alcohol Textbook Fourth Edition: The reference for the beverage, fuel ethanol industrial alcohol industries. Edited by K.A. Jacques, T.P. Lyons, D.R. Kelsall. Published October 15, 2003, by Nottingham University Press.

We highly recommend purchasing a copy, as it provides technical insight from the distiller’s perspective, as to what goes into the development of a spirit. In particular, we used the chapter "Tequila production from agave: historical influences and contemporary processes" by Miguel Cedeño Cruz.

The 4th Edition:

www.whitelabs.com/merchandise-detail?id=91&type=MERCHANDISE

The 5th and 6th Editions:

www.lallemandbds.com/en/canada/ethanol-technology-institute/the-alcohol-textbook/

We also recommend reading hawaiibevguide.com/agave-spirits as that is the pre-cursor to this article.

Metl in the Náhuatl language, or maguey (de Sahagún et al., 1970), is more recently known as “agave,” a term used by botanist Carlos Linneo in 1793, who derived the word from the Greek word “agavus,” which means admirable and illustrious. For this guide, we referenced The Alcohol Textbook Fourth Edition: The reference for the beverage, fuel ethanol industrial alcohol industries. Edited by K.A. Jacques, T.P. Lyons, D.R. Kelsall. Published October 15, 2003, by Nottingham University Press.

We highly recommend purchasing a copy, as it provides technical insight from the distiller’s perspective, as to what goes into the development of a spirit. In particular, we used the chapter "Tequila production from agave: historical influences and contemporary processes" by Miguel Cedeño Cruz.

The 4th Edition:

www.whitelabs.com/merchandise-detail?id=91&type=MERCHANDISE

The 5th and 6th Editions:

www.lallemandbds.com/en/canada/ethanol-technology-institute/the-alcohol-textbook/

We also recommend reading hawaiibevguide.com/agave-spirits as that is the pre-cursor to this article.

Agave Biology and Cultivation

Agave are monocarpic plants which are those that flower, set seeds, and then die. This process is ultimately the way to tell the agave has reached full maturity. It is also a crassulacean acid metabolism (CAM) plant, that is, a plant that reduces the amount of water lost through respiration by opening its stomata at night and fixating CO2 to malate to produce malic acid using PEP carboxylase, which accumulates during the night when the temperature is cooler, and closes its stomata while breaking down the malic acid to use the CO2 for photosynthesis during the day. Though this metabolic process is similar to a cactus, the agave is in the lily and Ti leaf family.

To make tequila, only the agave species Agave Azul, also known as Agave tequilana, Blue Weber Agave, or Blue Agave may be used.

To make tequila, only the agave species Agave Azul, also known as Agave tequilana, Blue Weber Agave, or Blue Agave may be used.

The Chemical Composition of Agave Azul

Fructose is the monosaccharide that is fermented by yeast. However, fructose in agave is stored in complex chains called fructans, which must be broken down to be accessible to yeast for fermentation.

-

Sugars

-

Fiberous Solids

-

Phenols

<

>

Agave Sugar: Fructans and Agavins

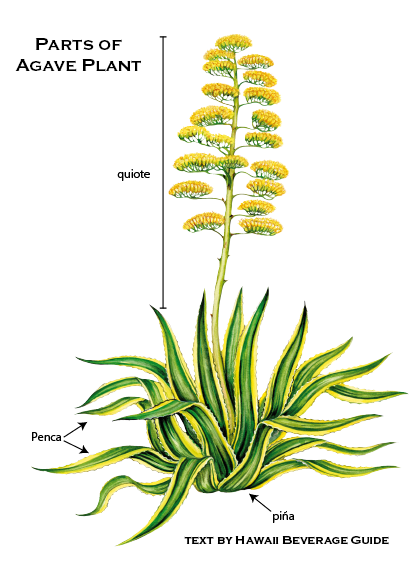

Fructans, a polymer of fructose molecules attached to one or more glucose molecules, are the primary type of sugar in agave, and the second most abundant nonstructural polysaccharides in nature (the most abundant being starch).1 They are primarily stored in the agave’s rhizome (piña), the key ingredient in agave spirits.

Fructans, a polymer of fructose molecules attached to one or more glucose molecules, are the primary type of sugar in agave, and the second most abundant nonstructural polysaccharides in nature (the most abundant being starch).1 They are primarily stored in the agave’s rhizome (piña), the key ingredient in agave spirits.

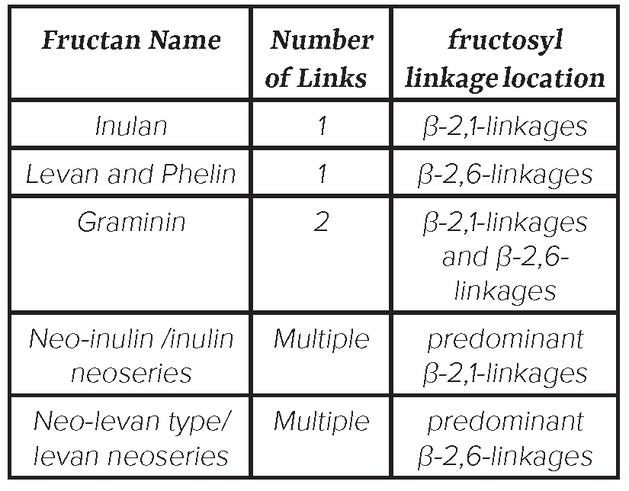

Classes of Fructans

(from Velazques-Martinez et al. 2014)

(from Velazques-Martinez et al. 2014)

Fructooligosaccharides (FOSs): Short chains of fructose and less complex than a fructan. These are indigestible and pass through the intestinal tract before being fermented in the large intestine by bacteria into lactate and short-chain fatty acids to yield 1–2 kcal/g rather than the 4 kcal/g of digestible carbohydrates.2

Fructans Accumulation Factors in agave:

Agave species have fructans that vary by molecular shape and the distribution of fructan types.3 However, we have not found any research on the organoleptic influence of the type of fructans present in agave. The primary fructans in Agave tequilana, for example, are branched inulin-levan type fructans which contain inulin, levan, and neo-inulin groups linked together4, rather than the previously-thought inulin type fructans.5

Fructans are affected by agave growing location and conditions, in particular, factors like climate, rainfall, altitude, and soil. For example, Mancilla-Margalli and López (2006) noted that in 6-year-old Agave tequilana propagated asexually by rhizomes:

Los Altos Jalisco

Penjamo, Guanajuato

An analysis of carbohydrates in Agave tequilana by Waleckx et al. 2008 found:

For more detailed insight into Agave fructans:

López, Mercedes G. & Mancilla-Margalli, N.A.. (2007). The nature of fructooligosaccharides in agave plants. Recent Adv. Fructooligosaccharides Res.. 47-67.

www.researchgate.net/publication/286685949_The_nature_of_fructooligosaccharides_in_agave_plants

Agave species have fructans that vary by molecular shape and the distribution of fructan types.3 However, we have not found any research on the organoleptic influence of the type of fructans present in agave. The primary fructans in Agave tequilana, for example, are branched inulin-levan type fructans which contain inulin, levan, and neo-inulin groups linked together4, rather than the previously-thought inulin type fructans.5

Fructans are affected by agave growing location and conditions, in particular, factors like climate, rainfall, altitude, and soil. For example, Mancilla-Margalli and López (2006) noted that in 6-year-old Agave tequilana propagated asexually by rhizomes:

Los Altos Jalisco

- Temperature Range: 8-22 °C

- Rainfall: 705-870 mm

- Average dry weight of soluble carbohydrates (WSC): 900 mg/g

Penjamo, Guanajuato

- Temperature Range: 18-24 °C

- Rainfall Range: 700-800 mm

- Average dry weight of soluble carbohydrates: 550 mg/g

- The high sea level and fresh nocturnal temperatures favor uptake of CO2 and consequently carbohydrate accumulation.

An analysis of carbohydrates in Agave tequilana by Waleckx et al. 2008 found:

- Fructans (93.4%)

- Free disaccharides (2.0%)

- Free glucose (0.8%)

- Free fructose (3.8%)

- Fructan bound glucose in agave as a ratio to glucose is estimated to be at least 1:15

For more detailed insight into Agave fructans:

López, Mercedes G. & Mancilla-Margalli, N.A.. (2007). The nature of fructooligosaccharides in agave plants. Recent Adv. Fructooligosaccharides Res.. 47-67.

www.researchgate.net/publication/286685949_The_nature_of_fructooligosaccharides_in_agave_plants

Fibrous solids aka bagasse (removed before fermentation)

- Comprise approximately 40% of the total wet weight of the milled agave.

- Composition (dry weight basis): 43% cellulose, 19% hemicellulose, 15% lignin, 3% total nitrogen, 1% pectin, 10% residual sugars, and 9% other compounds. [8]

- Bagasse is a byproduct of production and can be used

Agave Azul Phenolics

Beyond sugar, plant phenolics can provide organoleptic properties. For agave, there is limited research in regards to agave phenolics’ impact on the organoleptic properties of agave distillates, however there is research related to their potential medical usages. In a study by Morales-Serna et al. (2010) of Agave tequilana grown in Jalisco, Mexico, the primary phenolics in uncooked agave were homoisoflavanones of:9

The study, however, did not provide any organoleptic properties, nor are there any that we were able to find. We would hypothesize that during fermentation, these phenolics may be converted by enzymes into another aromatic molecule.

The agave-derived (rather than yeast or bacterial derived) phenolics in tequila distillate, as found by Alcazar Magana et al (2014), were: 10

For a literature review of agave phenolics:

Almaraz, Norma & Delgado, Amanda & Ávila-Reyes, José & Uribe-Soto, José & Gonzalez, Laura. (2013). The Phenols of the Genus Agave (Agavaceae). Journal of Biomaterials and Nanobiotechnology. 04. 9-16. 10.4236/jbnb.2013.43A002. https://doi.org/10.4236/JBNB.2013.43A002

Beyond sugar, plant phenolics can provide organoleptic properties. For agave, there is limited research in regards to agave phenolics’ impact on the organoleptic properties of agave distillates, however there is research related to their potential medical usages. In a study by Morales-Serna et al. (2010) of Agave tequilana grown in Jalisco, Mexico, the primary phenolics in uncooked agave were homoisoflavanones of:9

- •5,7-dihydroxy-3-(4-methoxybenzyl)-chroman-4-one

- •7-hydroxy-3-(4-hydroxybenzyl)-chroman-4-one

- •4-demethyl-3,9-dihydro-punctatin

The study, however, did not provide any organoleptic properties, nor are there any that we were able to find. We would hypothesize that during fermentation, these phenolics may be converted by enzymes into another aromatic molecule.

The agave-derived (rather than yeast or bacterial derived) phenolics in tequila distillate, as found by Alcazar Magana et al (2014), were: 10

- The main source of small phenolic compounds in tequila are derived from maturation in wooden barrels. In particular these are: syringic, vanillic, protocatechuic acids.

- Homovanillic acid was present in all three tequila types and in almost all samples. The authors suggest the compound may originate as-is from the A. tequilana plant, or may be formed during the tequila manufacturing process.

For a literature review of agave phenolics:

Almaraz, Norma & Delgado, Amanda & Ávila-Reyes, José & Uribe-Soto, José & Gonzalez, Laura. (2013). The Phenols of the Genus Agave (Agavaceae). Journal of Biomaterials and Nanobiotechnology. 04. 9-16. 10.4236/jbnb.2013.43A002. https://doi.org/10.4236/JBNB.2013.43A002

Agave Azul Cultivation

The cultivation and harvest of agave is highly influential on the final product. Due to the long growth period and high demand for agave, shortages arise. To figure out alternative solutions, research has been conducted.

-

Climate and Soil

-

Stage of Growth

-

Agave Age

<

>

Climate

(from Cedeño Cruz, 2003)

Temperature: Minimum of 3°C, an optimum of 26°C and maximum of 47°C.

Soil:

(from Cedeño Cruz, 2003)

Temperature: Minimum of 3°C, an optimum of 26°C and maximum of 47°C.

Soil:

- A depth of 30-40 cm.

- Adequate levels of nitrogen, phosphorus, potassium, and boron are required to not impede growth.11 This can be supplemented with fertilizers, including distillery effluent (vinasse) which was found to increase potassium, magnesium, and calcium.12

- Good drainage is essential, as the region floods regularly, which can produce detrimental effects.

- Planting season: June to September which is immediately before the rainy season. This reduces the plant’s water stress during the first year of growth.

Stages of Growth

(from Acosta-Salazar et al. 2021):

(from Acosta-Salazar et al. 2021):

- First stage (from 1 to 3 years): The plant generates its fundamental structure for its subsequent growth.

- Second stage (from 4 to 7 years): Almost exponential increase in size as the plant begins to store water and sugars. For example, Acosta-Salazar et al. 2021 found weight increases of:

- Years 4-5: Weight increase of 12.5%

- Years 5-6: Weight increase of 23.18%

- However, the specific amount of increase is not as important as the trend that exponential growth occurs between years five and six.

- Final stage (from the seventh year): The reproductive phase begins. This reduces the concentration of sugars and ends its life cycle.

Impact of agave age on tequila

Agave age is influential on the final product because of differences in the concentration of compounds, which in turn impacts fermentation. It is confirmed however that the characterization of the final product showed the feasibility to use agaves (less than 7 years) to produce the Tequila 100% agave silver class and to comply with the quality criteria (Acosta-Salazar et al. 2021). We will be citing the following two studies periodically throughout this piece.

Other Major Morphological and Chemical Differences

Nitrogen content

(from Acosta-Salazar et al. 2021)

Nitrogen content in the must is correlated to the agave’s age, with younger plants having less nitrogen. The authors attributed this to the nutrient addition to support the plant growth in the early years, where the development of the plant structures is prioritized before sugar production, resulting in a higher nitrogen content in the juice. The study shows a significant difference between 4-year vs. 6-year agave.

Nitrogen deficiencies typically require the addition of diammonium phosphate (DAP) to the fermentation. However, this can result in an unbalanced concentration of phosphorus in the must.

Agave age is influential on the final product because of differences in the concentration of compounds, which in turn impacts fermentation. It is confirmed however that the characterization of the final product showed the feasibility to use agaves (less than 7 years) to produce the Tequila 100% agave silver class and to comply with the quality criteria (Acosta-Salazar et al. 2021). We will be citing the following two studies periodically throughout this piece.

- Pinal et al. 2009: The differences between Agave tequilana juice of different ages (4 and 8 years) and of different cultivation fields after cooking, and through fermentation. It should be noted that the study was to show if there were differences, but not to specifically define the underlying causes of the differences.13

- Acosta-Salazar et al. 2021: Agaves of 4, 5 and 6 years of age in industrial scale quantities (used to average out the differences between individual agave), were used to make individual batches of tequila using a masonry oven and roller mill.

Other Major Morphological and Chemical Differences

- Younger agave have a lower weight and lower juice/exudate ratio (Acosta-Salazar et al. 2021).

- Exudate/sweet exudate/cooking honey is liquid produced during hydrolysis that is easily drained out of the oven.

- Agave juice is the liquid that results from milling.

Nitrogen content

(from Acosta-Salazar et al. 2021)

Nitrogen content in the must is correlated to the agave’s age, with younger plants having less nitrogen. The authors attributed this to the nutrient addition to support the plant growth in the early years, where the development of the plant structures is prioritized before sugar production, resulting in a higher nitrogen content in the juice. The study shows a significant difference between 4-year vs. 6-year agave.

Nitrogen deficiencies typically require the addition of diammonium phosphate (DAP) to the fermentation. However, this can result in an unbalanced concentration of phosphorus in the must.

Harvest

|

Agave tequilana Harvest Specifications

(from Cedeño Cruz, 2003)

Harvest process: Penca removal

As we mentioned in our article on agave spirits, which can be found at hawaiibevguide.com/ agave-spirits, the penca (leaf) is removed in the field, but the degree to which the penca is removed varies by producer. Cedeño Cruz (2003) noted that the agave penca has a thick, waxy cuticle which prevents damage to the leaf from high temperatures, but dissolves in the distillation step and produces a haze in the final product when it is diluted or cooled. The impact of the cuticle can be minimized through the quantity of post-harvest removal or post-distillation treatment, which can include activated charcoal and/or filtration through pure cellulose filter pads. This filtration can result in the loss of some aromas, however. |

Agave receiving process

Cedeño Cruz noted that once the agave is transported to the production facility and often checked using Modified AOAC (1990) procedures which determine: reducing sugar content (after acid hydrolysis of inulin), pH, moisture, dry weight, juice and ash content (Cedeño Cruz, 2003). |

Cooking: The hydrolysis of Fructans

The cooking of agave is one of the most significant processes in the generation of flavor in tequila, and probably equally as influential as fermentation or distillation. One may be able to say that the agave cooking process in agave spirit production has a similar impact to the kilning or roasting of malts in beer production.

Mechanism: Hydrolysis

Hydrolyzation is the process of breaking the chemical bonds between the polysaccharides into monosaccharides that are usable by yeast. In the case of agave, the polysaccharide fructans results in fructose by the application of:

Hydrolyzation is the process of breaking the chemical bonds between the polysaccharides into monosaccharides that are usable by yeast. In the case of agave, the polysaccharide fructans results in fructose by the application of:

- An acidic environment (pH of 4.0-4.5)

- Heat (95°-130°C)

General Cooking Procedures

(from Waleckx et al. 2008):

Masonry ovens were used in the primary studies on the cooking of Agave tequilana.

Temperature can be divided into two different periods:

(from Waleckx et al. 2008):

Masonry ovens were used in the primary studies on the cooking of Agave tequilana.

Temperature can be divided into two different periods:

- The first 30 hours of cooking: Temperature varied between 66.5-78.5 °C

- The last 6 hours: Temperature decreased to <50 °C due to the termination of vapor injection.

- The products of cooking are

- Bitter honey is produced and discarded.

- Exudate/sweet exudate/cooking honey is developed when a part of the vapor is condensed and accumulates in the oven (or autoclave). The condensed steam begins to extract sugars and other compounds from the agave heads by diffusion, generating a sweet juice.

- Cooked agave is then milled to extract a second sweet juice known as ‘‘agave juice.” This juice is blended with the cooking honey and fermented.

Changes during the Cooking Process

-

Color

-

pH

-

Carbohydrates

<

>

Changes During the Cooking Process: Color

Color of the cooking honey became darker during the cooking step. (Waleckx et al. 2008, Mancilla-Margalli and Lopez 2002). The darkening of color may be due to:

Color of the cooking honey became darker during the cooking step. (Waleckx et al. 2008, Mancilla-Margalli and Lopez 2002). The darkening of color may be due to:

- Caramelization, the pyrolysis of certain sugars (Waleckx et al. 2008). Fructose is known to contribute more noticeably to browning via caramelization than glucose (Mancilla-Margalli and Lopez 2002).

- Maillard reaction, which are heat reactions between amino acids and sugars, result in the accumulation of furfural, 5-(hydroxymethyl) furfural and pre-melanoidins, although carotenoids and other pigments may also contribute to the brown color (Mancilla-Margalliand Lopez 2002). pH of cooking honey decreases (becomes more acidic) as a function of cooking time (Waleckx et al. 2008, Mancilla-Margalli and Lopez 2002).

pH of cooking honey decreases (becomes more acidic) as a function of cooking time (Waleckx et al. 2008, Mancilla-Margalli and Lopez 2002).

According to Mancilla-Margalli and Lopez (2002), the pH decrease may be due to:

According to Mancilla-Margalli and Lopez (2002), the pH decrease may be due to:

- The formation of organic acids.

- The inability of amino moieties to act as bases when the amino compounds have reacted during Maillard reactions.

- The organic acids initially present in the plant, as well as other acidic compounds, are liberated in the cooking honey.

Carbohydrate transformations during cooking

The composition of cooking honey leveled after 25.5 hours of thermal treatment, with 98% of fructan oligomers being hydrolyzed (Waleckx et al. 2008). The changes in total carbohydrate proportions were:

The changes in total carbohydrate proportions were:

The composition of cooking honey leveled after 25.5 hours of thermal treatment, with 98% of fructan oligomers being hydrolyzed (Waleckx et al. 2008). The changes in total carbohydrate proportions were:

The changes in total carbohydrate proportions were:

- Fructans decreased from >80% to 5%

- Fructose increased from 12% to 80%.

- Glucose increased from 2% to 8%

- Disaccaharides (DP2)

- During the first 20 h of cooking During the first 20 hours of cooking, they increased from approximately 4.0% to 9.5%.

- During the final hours, they decreased to 6.5% of total carbohydrates.

- The increase, then decrease, may result from fructans being hydrolyzed into disaccharides before further hydrolysis into fructose.

Changes overtime showed:

- The initial flow of cooking honey: Minimal hydrolysis (percent hydrolysis: <20%, proportion of fructans: >80%, proportion of fructose: 12%)

- Maximum hydrolysis reached a maximum of 98% after 25.5 hours of cooking (Waleckx et al. 2008).

- The cooking honey produced in masonry ovens that is used in fermentation corresponds to a mix of cooking honey released during the duration of the cooking process, and results in a mix between slightly hydrolyzed honey (onset of flow) and increasingly hydrolyzed honey (cooking evolution). This unhydrolyzed portion of the cooking honey is non-fermentable and can result in up to a 6% loss in the total ethanol produced.

- The drastic increase in both carbohydrate content and °Brix cannot be explained only by the hydrolysis of fructan oligomers. We can assume that with an increased cooking time, more sugars are solubilized, due to a decrease in agave consistency and, subsequently, better diffusion conditions are encountered for these soluble compounds.

The Formation of Maillard Compounds

-

Maillard Compound Formation

-

Significant Maillard Compounds

<

>

Maillard Compound Formation

Maillard reactions occur when nucleophilic amino groups in amino acids react with reactive carbonyl groups in sugars to produce compounds that commonly give browned food its roasted and toasted flavors. While the general formation of Maillard compounds is understood and has been extensively studied, the research on what compounds are transformed and produced is ongoing. This is due to some compounds being generated in both Maillard and non-Malliard reactions, as well as compounds being influenced by the type and concentration of reactant, as well as the reaction conditions, which include the specific temperature at which the reaction occurs. This means that studies on the influence of Maillard reactions in the agave cooking process will generally provide perspective on trends in Maillard compound formation, but not necessarily specific contents. If done at the industrial scale, the cooking parameters used in each distillery and the quality and age of the agave will vary.

Mancilla-Margalli and Lopez (2002) [15] studied the Maillard reaction compounds generated by agave hydrolysis in masonry ovens over 28 hours, and analyzed cooking honey (exudate). It was found that >240 compounds in each exudate, plus a list of the principal compounds in the agave pine exudates and their abundance with cooking time was created. Other observations and hypotheses include:

Maillard reactions occur when nucleophilic amino groups in amino acids react with reactive carbonyl groups in sugars to produce compounds that commonly give browned food its roasted and toasted flavors. While the general formation of Maillard compounds is understood and has been extensively studied, the research on what compounds are transformed and produced is ongoing. This is due to some compounds being generated in both Maillard and non-Malliard reactions, as well as compounds being influenced by the type and concentration of reactant, as well as the reaction conditions, which include the specific temperature at which the reaction occurs. This means that studies on the influence of Maillard reactions in the agave cooking process will generally provide perspective on trends in Maillard compound formation, but not necessarily specific contents. If done at the industrial scale, the cooking parameters used in each distillery and the quality and age of the agave will vary.

Mancilla-Margalli and Lopez (2002) [15] studied the Maillard reaction compounds generated by agave hydrolysis in masonry ovens over 28 hours, and analyzed cooking honey (exudate). It was found that >240 compounds in each exudate, plus a list of the principal compounds in the agave pine exudates and their abundance with cooking time was created. Other observations and hypotheses include:

- Maillard compounds are produced by a dynamic transformation process, as compounds appear and disappear.

- The concentration of Maillard compounds changes over time. This is significant, as agave honey with these varying profiles is collected throughout the cooking process.

- Caramelization may also take place, generating alpha-dicarbonyl intermediates via retro aldolization, which are precursors of oxygen heterocyclic compounds, but it may also be insignificant.

- The presence of sulfur, amino heterocyclic molecules, and products of Strecker degradation is indicative of the Maillard reaction being the main process during the cooking of agave piña.

Maillard Compounds (by class):

Significant Mailliard Compounds

(Pyrans) 2,3-dihydroxy-3,5-dihydro-6-methyl-4(H)-pyran-4- one

(Pyrans) 2,3-dihydro-2-methyl-4(H)-pyran-4-one

See Agave Aroma Compounds Section

(Furans) 5-(hydroxymethyl)furfural

See Agave Aroma Compounds Section

Other significant Maillard compounds relevant to tequila:

Tequila Cooking Techniques

(from Cedeño Cruz, 2003)

Maillard compounds formed during cooking of agave pines are largely dependent on cooking parameters; therefore, the differences in the flavor characteristics between tequilas can be changed, directed, and/or controlled not only throughout the resting (reposado) and/or aging (an˜ejo) process but also during the cooking step (Mancilla-Margalli and Lopez, 2002).

- Primary compound classes (in decreasing amounts): Furans, pyrans, sulfur compounds, and ketones.

- Secondary compounds: benzyl alcohol, benzaldehyde, 3-hydroxy-2-butanone, and acetic acid.

Significant Mailliard Compounds

(Pyrans) 2,3-dihydroxy-3,5-dihydro-6-methyl-4(H)-pyran-4- one

- Aroma Influence: Sweet, caramelized odor16

- Production Mechanism: Could be formed by the interaction between fructose or glucose, with amino acids such as alanine, phenylalanine, serine, leucine, threonine, glycine, glutamine, or lysine.

(Pyrans) 2,3-dihydro-2-methyl-4(H)-pyran-4-one

- Aroma influence: Sweet, caramelized odor (Preininger et al 2009)

- Production Mechanism

- Could be formed by fructose-alanine interaction alone.

See Agave Aroma Compounds Section

(Furans) 5-(hydroxymethyl)furfural

See Agave Aroma Compounds Section

Other significant Maillard compounds relevant to tequila:

- (Lactone) beta-damascenone

- Organic acids

- Phenolic derived compounds, including vanillin, syringaldehyde, phenol, and phenol derivatives

- Alcohols, including 1-hexanol, 3-methyl-1-butanol, and phenylethyl alcohol

- 1-octen-3-ol (alcohol)

- Aroma influence: shellfish and tomato; it has been considered the most important odorant in mushrooms such as huitlacoche (Ustilago maydis, or corn smut) and Austern Pilzen (Pleurotus sp.).

- Benzaldehyde in the exudates adds green, floral, notes with a threshold of 4 ppb.

- Phenylacetaldehyde has a flowery odor.

- â-Damascenone is known for its woody, sweet, fruity, and floral descriptors.

- For a more complete understanding of these aroma compounds, see Agave Aroma Compounds Section.

Tequila Cooking Techniques

(from Cedeño Cruz, 2003)

Maillard compounds formed during cooking of agave pines are largely dependent on cooking parameters; therefore, the differences in the flavor characteristics between tequilas can be changed, directed, and/or controlled not only throughout the resting (reposado) and/or aging (an˜ejo) process but also during the cooking step (Mancilla-Margalli and Lopez, 2002).

Differences in cooking techniques

(Notes from Fernando Avila, Master Distiller of Sauza Tequila)

- Time

- Temperature

- Pressure: This is also significant because many distilleries are located at an elevation significant enough to impact the boiling point of water.

- Heat source: Steam is typical, direct fire is also an option.

- Control over the cooking environment (especially temperature and pressure). This prevents undercooking, overcooking, or uneven cooking. “Overcooked” notes provide a smoky flavor to the tequila, increase the concentration of furfural in the final product, and reduce ethanol yield, due to the caramelization/degradation of some fructose.

- Microbial control (easier to clean) minimizes unintended inoculation.

Agave Cooking Techniques

-

Masonry (Brick) ovens

-

Autoclaves

-

Acid hydrolysis and heat

<

>

Cooking Technical:

Process:

- Cooking Method: Steam

- Duration: 36-48 hours

- Temperatures of 100°C.

- Environmental Control: Some

- Microbial Control: Some

Process:

- Raw agave is chopped into uniform pieces.

- Steam is injected into the oven for 36-48 hours.

- Steam is shut off and the agave is left in the oven for two more days to complete the cooking process. During this step, ‘cooking honey’ is collected and the agave is cooled by opening the oven door.

Autoclaves are essentially industrial-sized pressure cookers. They are used in a variety of applications, due to their precise control over the heating environment.

Cooking Technical

Duration: ~13 hours

Process

Cooking Technical

- Cooking Method: Heat and Pressure

Duration: ~13 hours

- Cooking Temperature: Up to 121°C

- Environmental Control: High

- Microbial Control: High

Process

- If agave is whole: It is chopped into uniformed pieces (typically in half or quarters) before cooking in horizontal autoclaves.

- If agave is extracted in a diffuser: Liquid is pumped into vertical autoclaves.

- Steam is injected into a pressurized oven for 1 hr which steam washes the agave. The resulting liquid, called ‘bitter honey’, is discarded because it contains waxes from the agave cuticle and has a low sugar content (<1 % w/w).

- Steam is injected for an additional 6 hrs to obtain a pressure of 1.2 kg/cm2 and a temperature of 121°C.

- The agave remains in the autoclave for another 6 hrs without additional steam, cooking slowly in the remaining heat. This step produces a syrup with a high sugar concentration (>10% by weight) that is later used to formulate the initial wort.

Cooking Technical

Process:

- Cooking Method: Heat and Acidic Conditions of pH of 1.8–3.

- Duration: ~8 hours

- Cooking Temperature: 80–85 °C

Process:

- A diffuser is used to extract water soluble agave solids.

- Acid and heat are applied.

- •Cooking Method: Acid without heat is used to hydrolyze fructans.

- •Rarely used

Alternatives to Acid Hydrolysis

Alternatives to acid hydrolysis re being explored. One option is enzymatic hydrolysis using a black mold strain.

For more about enzymatic hydrolysis:

Carlos Huitrón, Rosalba Pérez, Luís Gutiérrez, Patricia Lappe, Pavel Petrosyan, Jesús Villegas, Cecilia Aguilar, Leticia Rocha-Zavaleta, Abel Blancas, Bioconversion of Agave tequilana fructans by exo-inulinases from indigenous Aspergillus niger CH-A-2010 enhances ethanol production from raw Agave tequilana juice, Journal of Industrial Microbiology and Biotechnology, Volume 40, Issue 1, 1 January 2013, Pages 123–132, doi.org/10.1007/s10295-012-1211-0

Avila-Fernández, A., Rendón-Poujol, X., Olvera, C., González, F., Capella, S., Peña-Alvarez, A., & López-Munguía, A. (2009). Enzymatic hydrolysis of fructans in the tequila production process. Journal of agricultural and food chemistry, 57(12), 5578–5585. doi.org/10.1021/jf900691r www.academia.edu/28608840/Enzymatic_Hydrolysis_of_Fructans_in_the_Tequila_Production_Process

Alternatives to acid hydrolysis re being explored. One option is enzymatic hydrolysis using a black mold strain.

For more about enzymatic hydrolysis:

Carlos Huitrón, Rosalba Pérez, Luís Gutiérrez, Patricia Lappe, Pavel Petrosyan, Jesús Villegas, Cecilia Aguilar, Leticia Rocha-Zavaleta, Abel Blancas, Bioconversion of Agave tequilana fructans by exo-inulinases from indigenous Aspergillus niger CH-A-2010 enhances ethanol production from raw Agave tequilana juice, Journal of Industrial Microbiology and Biotechnology, Volume 40, Issue 1, 1 January 2013, Pages 123–132, doi.org/10.1007/s10295-012-1211-0

Avila-Fernández, A., Rendón-Poujol, X., Olvera, C., González, F., Capella, S., Peña-Alvarez, A., & López-Munguía, A. (2009). Enzymatic hydrolysis of fructans in the tequila production process. Journal of agricultural and food chemistry, 57(12), 5578–5585. doi.org/10.1021/jf900691r www.academia.edu/28608840/Enzymatic_Hydrolysis_of_Fructans_in_the_Tequila_Production_Process

Milling:

Extraction of agave juice

The objective in milling agave is technically the physical process of removing sugar from the cooked agave piña.

The key differences between milling styles:

•The percentage of extracted non-fibrous materials removed from the agave.

•The speed at which extraction occurs.

•If the process influences the microbiome of the agave fermentation.

We found no scientific literature on the breakage of agave fibers influencing the fermentation process and/or the development of methanol, because it is not likely to have an influence. Given that: Breaking the fiber results in a physical rather than chemical breakdown of the lignocelluloses (lignin-cellulose-hemicellulose) fibers (the same compounds that make up oak barrels but in different quantities), and that the fibers are not known to experience enzymatic, or microbial degradation, no methanol producing pathways seem likely. However, the anecdotal notation of this phenomenon is most likely due to the increased extraction of the non-fibrous material from the agave, which includes an increase in the quantity of methylated compounds being extracted.

•The percentage of extracted non-fibrous materials removed from the agave.

•The speed at which extraction occurs.

•If the process influences the microbiome of the agave fermentation.

We found no scientific literature on the breakage of agave fibers influencing the fermentation process and/or the development of methanol, because it is not likely to have an influence. Given that: Breaking the fiber results in a physical rather than chemical breakdown of the lignocelluloses (lignin-cellulose-hemicellulose) fibers (the same compounds that make up oak barrels but in different quantities), and that the fibers are not known to experience enzymatic, or microbial degradation, no methanol producing pathways seem likely. However, the anecdotal notation of this phenomenon is most likely due to the increased extraction of the non-fibrous material from the agave, which includes an increase in the quantity of methylated compounds being extracted.

Types of Milling

-

Hand crushed with mallets

-

Stone Wheel: Tahona

-

Rollermill (Shredder)

-

Diffuser

<

>

Hand crushed with mallets (canoas y masos)

- Process: The traditional way to crush agave was by hitting it in a hollowed out tree trunk with wooden mallets/bats called canoas y masos before adding it to the fermentation tank. In this process, the agave fibers are not broken.

- Sugars removed: Low

- Fermentation Microbiome influence: High

Stone Wheel: Tahona (tequila)/ Molino (mezcal)

- Process: A volcanic stone wheel, or a wheel made from cement and wire weighing up to three tons, is pulled in a circle and mashes the agave into a fibrous pulp with minimal breakage of fibers. The pulling of the tahona was traditionally done by mules, horses, or oxen. It is now typically powered by a motor. The resulting juice was collected by hand in wooden basins and carried to fermentation tanks.

- Fermentation microbiome influence: High, because the stone is difficult to clean. It will inevitably accumulate inoculants, which can add to the microbiome of the tequila fermentation. The usage of the horse or other draft animal will even further add to the microbiome of the fermentation.

- Yield: This will generally mill one ton per day.

Rollermill (Shredder)

- Process: Similar to the shredders used in the sugarcane industry and implemented by the tequila industry in the 1950s, these machines first shred the cooked agave, then may use water to extract sugars.

- Sugars Removed: Medium to High.

- Fermentation microbiome influence: Medium, as these can be cleaned better than a tahona as they are made of non-porous material.

- Yield: Medium to high, depending on the specific equipment used.

Diffusion band extraction aka Diffuser

(Insight from Fernando Avila, Master Distiller of Sauza Tequila)

Diffusion is the scientific term that refers to when a substance moves from high concentration to a lower concentration, much like how tea or coffee is made. In the case of agave, diffusion band extraction is the fancy way to say that warm water was used to dissolve the agave sugars. The equipment for this process was initially commercialized in the extraction of sugar, and then in the extraction of alcohol from grapes in Spain (Cedeño Cruz, 2003).

Process:

Sugars Removed: Almost complete sugar extraction from the bagasse, with more than 95% of sugar extraction by lixiviation.

Microbiome Influence: Low to none.

Yield: High

Extraction Advantages

(Insight from Fernando Avila, Master Distiller of Sauza Tequila)

Diffusion is the scientific term that refers to when a substance moves from high concentration to a lower concentration, much like how tea or coffee is made. In the case of agave, diffusion band extraction is the fancy way to say that warm water was used to dissolve the agave sugars. The equipment for this process was initially commercialized in the extraction of sugar, and then in the extraction of alcohol from grapes in Spain (Cedeño Cruz, 2003).

Process:

- Previously shredded agave, which may be hydrolyzed or unhydrolyzed, depending on the producer, is put on a conveyor belt.

- Water is added so that it filters through the shredded agave and falls into collectors in the bottom of the diffuser. As water is the best sugar solvent, it dissolves the agave solids to produce a “juice.”

- The collected “juice” is pumped back onto the agave until the liquid is completely saturated with sugar.

- Once completely saturated:

- If the agave was hydrolyzed, the water will be used in fermentation

- If the agave was un-hydrolyzed, the collected water will be cooked in an autoclave.

Sugars Removed: Almost complete sugar extraction from the bagasse, with more than 95% of sugar extraction by lixiviation.

Microbiome Influence: Low to none.

Yield: High

Extraction Advantages

- Critical process parameters are controlled (temperature, pressure, velocity).

- Juice is collected on pipelines, avoiding contamination of juice.

- There is no spillage or floor runoff.

- Leftover sugars in bagasse are minimized. All bagasse is treated to become compost for use in new plantations.

- Water and energy usages are reduced, for a favorable environmental impact.

- Example of Diffusion Band Extractor Tomsa Destil tomsadestil.com.mx/en/agave_sugarcane_diffusion_milling.php

Fermentation

(100% agave tequila)

-

Yeast

-

Bacteria

-

Mezcal Yeast

<

>

Tequila Yeast

Agave fermentations are typically a combination of multiple yeasts, lactic acid and acetic acid bacteria species.18 These strains may be added through purposeful inoculation by Saccharomyces cerevasiae or spontaneous fermentation. A collection of yeast strains isolated and selected from tequila fermentations are deposited in the national microbial culture collections at the Biotechnology and Bioengineering Department Culture Collection of CINVESTAV-IPN, located In Mexico City (Cedeño Cruz, 2003).

Types of Agave Yeast

(Both Saccharomyces and non-Saccharomyces strains are typical in agave fermentations) One of the frequently cited studies of tequila yeast is Lachance (1995), although visual rather than genetic identification of yeast was used. Therefore, understandings should be coupled with more recent studies for a more accurate understanding of spontaneous yeast populations. In the study, it was found19:

Fresh Agave contained:

•Dominant Yeast: Clavispora lusitaniae and Metschnikowia agaves

•Secondary Yeast: Kloeckera marxianus and Pichia membranifaciens

Cooked Agave

Schizosaccharomyces pombe and lower numbers of Kloeckera marxianus.

Fresh must, and crushing equipment:

Dominant Yeast: Torulaspora delbrueckii, Hanseniaspora vineae, Saccharomyces cerevisiae

In earlier fermentation stages:

•Dominant Yeast: Torulaspora delbrueckii, Hanseniaspora species, Brettanomyces (Dekkera bruxellensis), Saccharomyces cerevisiae.

•Secondary Yeast: Zygosaccharomyces bailii and Candida milleri, Hanseniaspora guilliermondii, Hanseniaspora vinae, Kloeckera marxianus, Pichia membranifaciens, and Torulaspora delbrueckii were present as secondary yeasts.

As fermentation progressed species diversity was considerably reduced.

•Dominant Yeast: Saccharomyces cerevisiae

•Secondary Yeast: Pichia membranaefaciens in the surface film of older fermentations with Pichia kluyveri and one strain of Pichia membranaefaciens exhibiting growth in the presence of up to 7% ethanol.

•Substantial foaming, which was linked with a high abundance of Candida milleri and Zygosaccharomyces bailii.

Yeast Species Impact on Fermentation

A study on the differences between Saccharomyces cerevisiae and Hanseniaspora/Kloeckera apiculata by Arellano et al. 2008 found20:

Agave fermentations are typically a combination of multiple yeasts, lactic acid and acetic acid bacteria species.18 These strains may be added through purposeful inoculation by Saccharomyces cerevasiae or spontaneous fermentation. A collection of yeast strains isolated and selected from tequila fermentations are deposited in the national microbial culture collections at the Biotechnology and Bioengineering Department Culture Collection of CINVESTAV-IPN, located In Mexico City (Cedeño Cruz, 2003).

Types of Agave Yeast

(Both Saccharomyces and non-Saccharomyces strains are typical in agave fermentations) One of the frequently cited studies of tequila yeast is Lachance (1995), although visual rather than genetic identification of yeast was used. Therefore, understandings should be coupled with more recent studies for a more accurate understanding of spontaneous yeast populations. In the study, it was found19:

Fresh Agave contained:

•Dominant Yeast: Clavispora lusitaniae and Metschnikowia agaves

•Secondary Yeast: Kloeckera marxianus and Pichia membranifaciens

Cooked Agave

Schizosaccharomyces pombe and lower numbers of Kloeckera marxianus.

Fresh must, and crushing equipment:

Dominant Yeast: Torulaspora delbrueckii, Hanseniaspora vineae, Saccharomyces cerevisiae

In earlier fermentation stages:

•Dominant Yeast: Torulaspora delbrueckii, Hanseniaspora species, Brettanomyces (Dekkera bruxellensis), Saccharomyces cerevisiae.

•Secondary Yeast: Zygosaccharomyces bailii and Candida milleri, Hanseniaspora guilliermondii, Hanseniaspora vinae, Kloeckera marxianus, Pichia membranifaciens, and Torulaspora delbrueckii were present as secondary yeasts.

As fermentation progressed species diversity was considerably reduced.

•Dominant Yeast: Saccharomyces cerevisiae

•Secondary Yeast: Pichia membranaefaciens in the surface film of older fermentations with Pichia kluyveri and one strain of Pichia membranaefaciens exhibiting growth in the presence of up to 7% ethanol.

•Substantial foaming, which was linked with a high abundance of Candida milleri and Zygosaccharomyces bailii.

Yeast Species Impact on Fermentation

A study on the differences between Saccharomyces cerevisiae and Hanseniaspora/Kloeckera apiculata by Arellano et al. 2008 found20:

Bacteria Species (from Arellano et al. 2008)

Early phases of the fermentation

Older fermentations

Other species include: Streptococcus, Leuconostoc, and Pediococcus are the most common contaminants, but Acetobacter may be found in fermented worts that are left inactive for a long time prior to distillation (Cedeño Cruz, 2003).

Bacterial growth is dependent on:

Influence of Bacteria

For insight into differences in yeast species in different agave fermentations:

Patricia Lappe-Oliveras, Rubén Moreno-Terrazas, Javier Arrizón-Gaviño, Teófilo Herrera-Suárez, Abisaí García-Mendoza, Anne Gschaedler-Mathis, Yeasts associated with the production Yeasts associated with the production of Mexican alcoholic nondistilled and distilled Agave beverages, FEMS Yeast Research, Volume 8, Issue 7, November 2008, Pages 1037–1052, https://doi.org/10.1111/j.1567-1364.2008.00430.x

- Dominant Bacteria: Leuconostoc spp. and Lactobacillus spp. (both types of lactic acid bacteria)

Older fermentations

- Acetobacter aceti.

Other species include: Streptococcus, Leuconostoc, and Pediococcus are the most common contaminants, but Acetobacter may be found in fermented worts that are left inactive for a long time prior to distillation (Cedeño Cruz, 2003).

Bacterial growth is dependent on:

- The extent to which bacteria grow during yeast propagation (if used).

- The abundance of bacteria on the raw materials.

- Hygiene standards in the distillery.

Influence of Bacteria

- Bacteria can contribute to the organoleptic characteristics of the final product.

- Excessive bacterial growth can cause bacteria to use the sugars, decreasing ethanol yields, and sometimes excreting undesirable aroma compounds.

For insight into differences in yeast species in different agave fermentations:

Patricia Lappe-Oliveras, Rubén Moreno-Terrazas, Javier Arrizón-Gaviño, Teófilo Herrera-Suárez, Abisaí García-Mendoza, Anne Gschaedler-Mathis, Yeasts associated with the production Yeasts associated with the production of Mexican alcoholic nondistilled and distilled Agave beverages, FEMS Yeast Research, Volume 8, Issue 7, November 2008, Pages 1037–1052, https://doi.org/10.1111/j.1567-1364.2008.00430.x

Mezcal yeast [21]

Mezcal typically employs spontaneous fermentation. In a study by Nolasco-Cancino, Hipócrates et al, 2018, it was found:

We highly recommend reading the full study and will be elaborating on this process in the future:

Nolasco-Cancino, Hipócrates et al. “Predominant Yeasts During Artisanal Mezcal Fermentation and Their Capacity to Ferment Maguey Juice.” Frontiers in microbiology vol. 9 2900. 6 Dec. 2018, https://doi.org/10.3389/fmicb.2018.02900

Mezcal typically employs spontaneous fermentation. In a study by Nolasco-Cancino, Hipócrates et al, 2018, it was found:

- The fermentative yeast in order of abundance: Pichia kudriavzevii, Pichia manshurica, Saccharomyces cerevisiae, and Kloeckera marxianus

- In a mixed culture of

- Saccharomyces cerevisiae with Pichia kudriavzevii

- Kloeckera marxianus and Pichia kudriavzevii

- The ester type produced depends on the presence of bagasse in the maguey juice, where maguey juice without bagasse promotes the production of ethyl acetate, and no bagasse promotes the production of ethyl lactate.

- Kloeckera marxianus in maguey juice fermentation could be explained by its capacity to grow on fructans, as a result of its fructanase activity.

- Non-Saccharomyces species dominate in mezcal fermentations because ethanol concentrations are typically 4–6% v/v.

- Saccharomyces cerevisiae typically becomes the primary fermenter when ethanol concentrations reach 9–10% v/v because of its high ethanol tolerance.

We highly recommend reading the full study and will be elaborating on this process in the future:

Nolasco-Cancino, Hipócrates et al. “Predominant Yeasts During Artisanal Mezcal Fermentation and Their Capacity to Ferment Maguey Juice.” Frontiers in microbiology vol. 9 2900. 6 Dec. 2018, https://doi.org/10.3389/fmicb.2018.02900

Fermentation Factors

-

Fermenation Vessels

-

Wort Formulation

-

Temperature

-

Time

<

>

Fermentation vessels

- Size: 12,000 to 150,000 liters

- Material: Stainless steel

Wort formulation

(from Cedeño Cruz, 2003)

•Often based on previous experience.

Sugars and Alcohol

Common nutritional deficiency corrections:

(from Cedeño Cruz, 2003)

•Often based on previous experience.

Sugars and Alcohol

- Fermentation Must:

20 °Bx on average (Acosta-Salazar et al. 2021) - Sugar concentration: 4-10% w/v. Concentration depends on the amount of water added during milling.

- Final alcohol content: 4 and 9% v/v, depending on the initial sugar concentration.

- Begining pH: 4.5

- Final pH: drop from 4.5 to 3.9 is characteristic of the fermentation.

Common nutritional deficiency corrections:

- Addition of nitrogen using urea, ammonium sulfate, ammonium phosphate or magnesium sulfate.

- Because the pH of the agave juice is around 4.5, there is no need for adjustment, and the same wort composition is used for both inoculum growth and fermentation.

Fermentation temperature

(from Arellano et al. 2008)

(from Arellano et al. 2008)

- Ethanol concentration generally increases as temperature increases.

- Higher alcohols, esters and fatty acids increase with increases in temperature.

- Most of the distilleries are located in regions where ambient temperatures are normally warm and may be as high as 37º C during summer.

- Not all strains of Saccharomyces cerevisiae are resistant to the high temperatures of tequila fermentation, making the selection of a commercial strain critical.

- Once a wort is formulated with the required nutrients and the temperature is around 30° C, it may be inoculated with 5 to 10% (volume) of a previously grown Saccharomyces cerevisiae culture with a population of 100-200 million cells/ml. Otherwise, microorganisms present in the wort carry out the fermentation. If an inoculum is not added, the fermentation could last as long as seven days. With an inoculum, the fermentation time ranges from 20 hours in the faster process to three days in the slower one.

Fermentation Time

Age on Agave Impact on Fermentation

Cell growth of both yeast strains was not affected by the agave age, cultivation field and yeast strain (Pinal et al. 2009).

- The amount of organoleptic compounds produced is lower in fast fermentations than in slow fermentations (Cedeño Cruz, 2003).

- The rate of fermentation depends on: yeast strain used, medium composition and operating conditions.

- The wort sugar content decreases from an initial value of 4-11% to 0.4% (w/v) reducing sugars if an efficient yeast strain is employed. Otherwise, the residual sugar content could be higher, increasing production costs.

Age on Agave Impact on Fermentation

Cell growth of both yeast strains was not affected by the agave age, cultivation field and yeast strain (Pinal et al. 2009).

Fermentation Characteristics

- In order to increase the fermentation yield, enzymes or enzyme complexes can be added to the wort to convert residual agave polymers into fermentable sugars.

- Fermentations carried out with pure agave juice tend to foam, sometimes requiring the addition of silica. In worts with added sugars, foaming is usually not a problem.

- In contrast to other distilled beverages, the organoleptic characteristics of tequila come from the raw material (cooked agave) as well as from the fermentation process (Cedeño Cruz, 2003).

Distillation

Tequila, by law, requires at least double distillation. This can occur in a pot still or a pot still and reflux still. In either case, it is what is being selected that is the most important, with a general process being found here: hawaiibevguide.com/stills.

Distillation Process

•In the stripping run: Congeners are enriched because, in this stage, the alcoholic content on the fermented must is separated and concentrated.

•In the second distillation, the congener content can be sufficiently adjusted to obtain tequila 100% agave silver class as a product as defined by the CRT/NOM-006.

Distillation Process

•In the stripping run: Congeners are enriched because, in this stage, the alcoholic content on the fermented must is separated and concentrated.

•In the second distillation, the congener content can be sufficiently adjusted to obtain tequila 100% agave silver class as a product as defined by the CRT/NOM-006.

Key volatile compounds:

In distillation, there are the hearts, but the low boiling point compounds constituting the “heads” and the high boiling point compounds constituting the “tails” are what influence the spirit. In tequila, these are primarily:

Low boiling point compounds (heads) include:

•Acetaldehyde, ethyl acetate, methanol, 1- propanol, 2-propanol, 1-butanol, and 2-methyl propanol.

•These are regularly mixed back into the wort and redistilled (Cedeño Cruz, 2003).

Low boiling point compounds (heads) include:

•Acetaldehyde, ethyl acetate, methanol, 1- propanol, 2-propanol, 1-butanol, and 2-methyl propanol.

•These are regularly mixed back into the wort and redistilled (Cedeño Cruz, 2003).

In distillation, there are the hearts, but the low boiling point compounds constituting the “heads” and the high boiling point compounds constituting the “tails” are what influence the spirit. In tequila, these are primarily:

Low boiling point compounds (heads) include:

•Acetaldehyde, ethyl acetate, methanol, 1- propanol, 2-propanol, 1-butanol, and 2-methyl propanol.

•These are regularly mixed back into the wort and redistilled (Cedeño Cruz, 2003).

Low boiling point compounds (heads) include:

•Acetaldehyde, ethyl acetate, methanol, 1- propanol, 2-propanol, 1-butanol, and 2-methyl propanol.

•These are regularly mixed back into the wort and redistilled (Cedeño Cruz, 2003).

Still proof:

•110° proof if sold in bulk (then brought down to proof)

•80° proof if it is to be bottled.

To exemplify these adjustments, Acosta-Salazar et al. (2021) found:

•110° proof if sold in bulk (then brought down to proof)

•80° proof if it is to be bottled.

To exemplify these adjustments, Acosta-Salazar et al. (2021) found:

Barrel Aging of Tequila

Barrel aging is a complex mechanism, because there are elements which are simply extraction of barrel compounds, as well as secondary chemical reactions. For this reason, we will reserve discussion for another article. In the meantime, we suggest reading:

Hawaii Beverage Guide’s article on oak barrels:

www.hawaiibevguide.com/a-guide-to-oak-barrel-aging

Gonzalez-Robles, Ivonne & Cook, David. (2016). The impact of maturation on concentrations of key odour active compounds which determine the aroma of tequila: Key odour active compounds which determine the aroma of tequila. Journal of the Institute of Brewing. 122.

doi.org/10.1002/jib.333

Hawaii Beverage Guide’s article on oak barrels:

www.hawaiibevguide.com/a-guide-to-oak-barrel-aging

Gonzalez-Robles, Ivonne & Cook, David. (2016). The impact of maturation on concentrations of key odour active compounds which determine the aroma of tequila: Key odour active compounds which determine the aroma of tequila. Journal of the Institute of Brewing. 122.

doi.org/10.1002/jib.333

Aroma Compounds

in Tequila

The aroma compounds in tequila are numerous and complex. They are also regulated by NOM-006-SCFI-2012. To better understand what influences tequila flavor, we have utilized the aforementioned studies and the following that focus on aroma compound identification.

The Studies

- Arellano et al. 2008 studied the production of aroma compounds during Agave tequilana fermentation at 35° C in a laboratory environment, using select native yeast strains of S. cerevisiae and Kloeckera spp. [23]

- Prado-Jaramillo et al. 2015 studied the production of minor volatiles throughout tequila's elaboration process in two tequila distilleries in the Los Altos region in Jalisco, with sampling taken at the end of the following steps: raw agave, cooked agave, after milling, wort formulation, fermentation start after yeast addition, end of fermentation, first distillation and second distillation. [24]

The Five most odorous Compounds in Tequila

Of all the compounds in tequila, five were found by the often-cited Benn and Peppard (1996) to have the most significant aroma and flavor contribution. These aroma compounds, primarily generated during the cooking process, are: Isovaleraldehyde aka 3-methylbutanal, isoamyl alcohol, β-damascenone, 2-phenylethanol, and vanillin. [25]

Alcohols

-

Ethanol

-

Methanol

<

>

Ethanol

(from Pinal et al. 2009)

Quantity Influenced By:

(from Pinal et al. 2009)

Quantity Influenced By:

- Production rate was influenced by the agave cultivation field location and yeast strain, but not by agave age.

- Production quantity was age-dependent, as older agave had higher amounts of fructose. Four-year-old agaves had lower ethanol production than 8-year-old agaves independent of cultivation location, due to the lower quantity of sugar (though the study did not cite their measurements of dissolved solids/sugar between 4 and 8-year old agave).

Methanol

Production Mechanism

(from Cedeño Cruz, 2003)

During the cooking stage, methanol is thought to be generated through hydrolysis of methylated pectins. In this process, methyl group (CH3) is removed from the methylated pectin through demethylation. This leaves the pectin and a methyl group which binds with an -OH group to create methanol). Demethylation occurs:

Quantity Influenced By:

(from Pinal et al. 2009)

Production Mechanism

(from Cedeño Cruz, 2003)

During the cooking stage, methanol is thought to be generated through hydrolysis of methylated pectins. In this process, methyl group (CH3) is removed from the methylated pectin through demethylation. This leaves the pectin and a methyl group which binds with an -OH group to create methanol). Demethylation occurs:

- During the high pH and temperatures in the cooking of agave and the heating process during distillation.

- It is also believed that some yeast strains, natural or inoculated, have pectin methyl esterases, however this has not yet been demonstrated (Cedeño Cruz, 2003).

- Lignin varies by species, maturity, and stress during development. Methanol is formed during thermal hydrolysis by lignin demethylation, and, later, by enzyme activity degrading lignin and freeing methoxylated compounds that were not freed during thermal hydrolysis. Methanol removal may also impact overall aroma and flavor, because there are congenerics with molecular weights close to methanol weight that are also removed with methanol.

Quantity Influenced By:

(from Pinal et al. 2009)

- Methanol concentration depended on agave age, where methanol was higher in younger agave. It may be possible that with older agaves, less methoxyl groups of pectins are available for methanol production.

- Cultivation field.

- Methanol’s high concentrations in both distillation stages due to its boiling point (64.7° C), always remaining as part of the light compounds (volatile) known as “heads” (from Acosta-Salazar et al. 2021).

Higher Alcohols/Fusel oil/Fusel Alcohol

Higher alcohols are secondary yeast metabolites, and the most abundant in decreasing order are: isoamyl alcohol, isobutanol, active isoamyl alcohol, phenylethanol (Cedeño Cruz, 2003).

-

General Formation

-

Significant Higher Alcohols

<

>

General Production

Amount generally influenced by:

(Cedeño Cruz, 2003/ Acosta-Salazar et al. 2021)

Amount generally influenced by:

(Cedeño Cruz, 2003/ Acosta-Salazar et al. 2021)

- Agave age: Content decreases as the agave ages (Acosta-Salazar et al. 2021).

- pH

- Yeast strain (Cedeño Cruz, 2003)

- Fermentation temperature (Cedeño Cruz, 2003)

- Fermentation type

Moran-Marroquín et al. (2011) observed that, in a continuously fed fermentation, the amount of higher alcohols and esters decreased while acetaldehyde increased. - Carbon-to-nitrogen ratio (C:N) is highly influential, and in tequila production, the production of higher alcohols has been observed to increase as the carbon/nitrogen ratio increases (Pinal et al. 2009). This source also notes that the C:N ratio:

- Was higher in the must of 8-year-old agaves than in that of 4-year-old agaves, due to the fact that, despite equal nitrogen supplementation in all fermentations, the initial sugar concentration was lower in 4-year-old agaves. The higher C:N ratio in older agave may have caused the increase in the higher alcohols of 1-propanol, isobutanol and amyl alcohols production at the end of the fermentation, because they can be produced by the breakdown of amino acids, known as the Ehrlich pathway, or by anabolism of amino acids under nitrogen-limited conditions, where more αceto acids are decarboxylated and transformed to aldehydes and higher alcohols.

- In tequila fermentations, the must often has low levels of nitrogen because of the degradation of nitrogen by Maillard reactions during cooking.

- Arrizon and Gschaedler (2007) associated production of ethanol, higher alcohols, acetaldehyde and ethyl acetate with the kind of nitrogen source added to the must–(NH4)2SO4, glutamic acid and a mixture of amino acids–concluding that final quality of tequila could change due to the volatile compound synthesis change. 26

|

Amyl alcohols mainly Isoamyl Alcohol

(3-methyl-1-butanol) Aroma influence:

Isobutanol (C4-H10-O, 2-methylpropan-1-ol, 2-Methyl-1-propanol) 28 Aroma Influence:

Production Rate Influenced By:

|

N-propanol/1-propanol (propan-1-ol) Aroma Influence: Alcoholic, fermented, musty odor. 30 Production Mechanism: Synthesized during fermentation (Acosta-Salazar et al. 2021) with Arellano et al. 2008 noting that the metabolic pathway used by yeast may be one of the following:

Amount Influenced By:

Phenylethanol (2-Phenylethanol, 2-phenyl-ethanol) Aroma Influence:

Yeast metabolism Production Rate Influenced By:

|

Aldehydes

-

General Formation

-

Significant Aldehydes

<

>

General Production

(from Prado-Jaramillo et al. 2015)

(from Prado-Jaramillo et al. 2015)

- Some come from raw material (MP) and could disappear throughout the process.

- Others appeared only after first distillation, with no statistically significant differences between the first and second distillation; the slight appreciable increase may be attributable to the concentration of the analyte due to the second distillation step (Acosta-Salazar et al. 2021).

Acetaldehyde

Aroma Influence:

The oxidation of ethanol is an intermediate in the production of acetic acid (Cedeño Cruz, 2003).

Vanillin

Aroma Impact:

Quantity Influenced By:

Aroma Influence:

- Fruity character at low levels. At higher levels, a pungent odor and irritant effect is produced (Arellano et al. 2008).

- The official Mexican standard for tequila establishes that the maximum permissible level for acetaldehyde is 40 mg/L.

The oxidation of ethanol is an intermediate in the production of acetic acid (Cedeño Cruz, 2003).

Vanillin

Aroma Impact:

- The aroma of vanilla.

- May be formed by the thermal degradation of lignin during cooking (Mancilla-Margalli and Lopez 2002).

Quantity Influenced By:

- Cooking process

- Barrel aging, since it is a barrel constituent.

Esters

-

General Formation

-

Important Esters

<

>

.Esters

Esters make up the largest family of compounds in tequila.

General Formation Notes

from Prado-Jaramillo et al. 2015

General Amount Influence by

Agave age. Esters were found to be the highest after the second distillation in batches made with 4-year-old agave, because a lower juice/exudate ratio is required for younger agaves, thus, a greater amount of exudate is used in the must mix (Acosta-Salazar et al. 2021). Additionally, the exudate contains greater amounts of fatty acids (carboxylic acids), which at a higher temperature promote the esterification reaction with the alcohol in solution to produce more esters.

Esters make up the largest family of compounds in tequila.

General Formation Notes

from Prado-Jaramillo et al. 2015

- Esters are formed by the addition of an alcohol to the carbonyl group of an acid.

- Esters increased in concentration during fermentation and after each distillation at different rates. For example:

- After cooking: Methyl linolenate showed a significant decrease and disappeared.

- After fermentation: ethyl stearate and isobutyl acetate considerably increased, and isobutyl acetate moderately increased.

- During distillation, there was a dramatic increase of fatty acid esters (ethyl caprate, ethyl linoleate, ethyl palmitate, ethyl caprylate, ethyl laurate, and phenthyl caproate, as well as furfuryl formate).

General Amount Influence by

Agave age. Esters were found to be the highest after the second distillation in batches made with 4-year-old agave, because a lower juice/exudate ratio is required for younger agaves, thus, a greater amount of exudate is used in the must mix (Acosta-Salazar et al. 2021). Additionally, the exudate contains greater amounts of fatty acids (carboxylic acids), which at a higher temperature promote the esterification reaction with the alcohol in solution to produce more esters.

Ethyl acetate

Aroma Influence:

Production mechanism:

Amount influence by:

Other Important Esters

Aroma Influence:

- Imparts another fruity flavor in tequila, however, at a concentration higher than 150 mg/L, the ethyl acetate imparts undesirable characteristics to the alcoholic beverages (Arellano et al. 2008).

- The main ester that occurs in distilled tequila (Arellano et al. 2008) and the second most abundant compound in tequila after isoamyl alcohol (Cedeño Cruz, 2003).

Production mechanism:

- Yeast during fermentation where ethyl acetate is produced by the esterification of alcohol-acetyltransferase, which combines an ethanol molecule with an acyl group from acetyl-CoA, making variations in yeast metabolism significant (Pinal et al. 2009).

- Cedeño Cruz, 2003 also noted that quantity varies and is synthesized from acetic acid (in the form of acetyl CoA) and ethanol.

- Acetic acid can also be produced by the oxidation of ethanol, when the fermentation has ceased and an oxidative process starts on the surface of the fermentation tank by S. cerevisiae and many other yeasts such as Brettanomyces.

- Long fermentation periods (a current practice in the tequila industry) yield high ethanol oxidation.

- Open fermentation tanks with low pH worts allow ethanol to be transformed into acetic acid (it- self a precursor of ethyl acetate) by Acetobacter.

Amount influence by:

- Production was principally influenced by the yeast strain (Pinal et al. 2009).

- Yeast species, as Kloeckera spp. produced a significantly higher amount (6-fold of ethyl acetate) than the S. cerevisiae strains (Arellano et al. 2008).

- There is a significant concentration at the time of tequila distillation, in which it is important to maintain and regulate the concentration produced to be within the Mexican standard (Acosta-Salazar et al. 2021). • Ethyl acetate is the most abundant and important factor (17.7%) (Cedeño Cruz, 2003).

Other Important Esters

- Acetyl esters

- Formation: Acetals first appear at the end of the fermentation and increase during distillation, possibly because of the effect of their concentration, rather than de novo generation as with other compounds (Prado-Jaramillo et al. 2015)).

- Ethyl and isoamyl esters, including: Ethyl decanoate (2.78), Ethyl lactate (2.74), Ethyl octanoate (1.92), Ethyl dodecanoate (0.95), Ethyl butanoate (0.63), Isoamyl acetate (0.58), Ethyl propanoate (0.57), Ethyl hexanoate (0.48), and Ethyl hexadecanoate (0.48) (Cedeño Cruz, 2003 from Estarrón et al., 1999).

- Methyl esters

-

Furans

-

Ketones

-

Organic Acids (Fatty Acids)

<

>

Furans General Production All the identified furans appeared after cooking (Prado-Jaramillo et al. 2015). Significant Furans Furfal (from Acosta-Salazar et al. 2021) Aroma Influence: Sweet, caramel, bready. Production Mechanism: • Associated with the hydrolysis stage. The Maillard reactions are simultane- ously promoted by those conditions. Amount Influenced By: • Distillation practice. Furfural’s con- centration can be eliminated due to its high boiling point (161.7° C) and thus discarded together with all the heavy compounds (less volatile), known as “tails”. • The concentration of higher alcohols are correlated to their boiling point at 1 atm: n-propanol (97.1° C), 2-butanol (99° C), 2-methyl-1-propanol (108° C), n-butanol (117.7° C), and 3-methyl- 1-butanol (131° C); thus a higher con- centration of the first congeners is due to a prevalence on the lightweight components in distillation (heads), which gives the product a desirable organoleptic profile (Acosta-Salazar et al. 2021). (Furans) 5-(hydroxymethyl)furfural Aroma Influence: • Was the most abundant. • Buttery, caramel. Production Mechanism: • Increased throughout the whole cooking time. • Forms from both the dehydration and degradation of carbohydrates as well as from the Maillard reaction. Amount influenced by: Cooking technique

Ketones (from Prado-Jaramillo et al. 2015)

Aroma Influence: Varies.

Production Mechanism

Amount Influenced By: Cooking technique

Significant Ketones

Β-damascenone

Aroma Influence: Varies.

Production Mechanism

- A large number appeared after agave cooking.

- Others appeared after first distillation.

- Highest after cooking and milling. They can also be formed during fermentation, but in a low concentration that increases during distillation.

Amount Influenced By: Cooking technique

Significant Ketones

Β-damascenone

- Aroma influence: Floral, woody.

- Production mechanism: B-damascenone and a-Cyclocitral could be produced after cooking and/or distillation through the degradation of carotenoids (Mancilla-Margalli and Lopez 2002, Prado-Jaramillo et al. 2015).

Organic Acids (Fatty acids)

from Cedeño Cruz, 2003. Aroma Influence: N/A.

Production Mechanism:

Amount Influenced By:

from Cedeño Cruz, 2003. Aroma Influence: N/A.

- Octanoic acid: musty, pungent odor.

- Decanoic acid: Fatty, soapy odor.

Production Mechanism:

- Degradation of agave cell membranes during cooking, though acetic acid is also generated by the Strecker degradation of alanine (Mancilla-Margalli and Lopez (2002).

- Produced during fermentation. Fatty acids, in particular octanoic and decanoic acids, are synthesized for mem- brane structures during cell growth, and can also appear at the end of the fermentation when autolysis takes place.

- The smaller molecules can be products of intermediate metabolism of the normal microbial flora; their pro- duction depends on the presence of oxygen.

Amount Influenced By:

- Yeast strain

- Prado-Jaramillo et al. 2015 noted: The quantity of fatty acids could be attributed to agave geographical origin, agave species, and fermentation practices, including the strain of yeast used in fermentation as well as with the fermentation temperature.

-

Phenols

-

Sulfur Containing Compounds

-

Terpenes

-

Acetals

<

>

Phenols

from Prado-Jaramillo et al. 2015

Aroma Influence: Varies.

Production Mechanism:

from Prado-Jaramillo et al. 2015

Aroma Influence: Varies.

Production Mechanism:

- Few phenols appeared at cooking and may be generated in early stages in the process, but their concentration could be under the detection thresh- old of the analysis method.

- Most appear after the first distilla- tion. Amount Influenced by: See page 3.

Sulfur-Containing Compounds

Aroma Influence: Varies.

Production Mechanism:

Amount Influenced By:

Aroma Influence: Varies.

Production Mechanism:

- Most of the sulfur-containing com- pounds appeared after cooking (Pra- do-Jaramillo et al. 2015).

Amount Influenced By:

- No specific data found.

Terpenes

from Prado-Jaramillo et al. 2015

Aroma Influence: Varies.

Production Mechanism:

Amount Influenced By:

Significant Terpenes

from Prado-Jaramillo et al. 2015

Aroma Influence: Varies.

Production Mechanism:

- These compounds have been identified in different agave plants, including A. tequilana Weber (Prado-Jaramillo et al. 2015, Mancilla-Margalli and Lopez 2002).

- Terpenes are synthesized in plants in different biochemical pathways with specific enzymes having different objectives, such as defense against insect attack (Prado-Jaramillo et al. 2015).

- Terpenes could also be synthesized by different yeast strains, as has been shown in wines (Prado-Jaramillo et al. 2015).

Amount Influenced By:

- Geographical origin of A. tequilana plants (Prado-Jaramillo et al. 2015).

Significant Terpenes

- Linalool, phytol, and (Z)- and (E)-geraniol

- Production Mechanism: From the agave plant (Mancilla-Margalli and Lopez, 2002).

Acetals

(from Prado-Jaramillo et al. 2015)

Aroma Influence: Varies.

Production Mechanism:

Amount Influenced By:

(from Prado-Jaramillo et al. 2015)

Aroma Influence: Varies.

Production Mechanism:

- They appeared after fermentation, some of them only after distillation steps where its concentration increased.

- Formed by the addition of an alcohol to the carbonyl group of an aldehyde.

Amount Influenced By:

- No significant differences were found between batches and factories except for a few compounds.

- Between batches, only dipropyl disulfide is an important onion- or garlic-like odorant that could be produced from thermal degradation of S-propylcysteine sulfoxide.

Sources and Suggested Reading

- Velázquez-Martínez, J. R., González-Cervantes, R. M., Hernández-Gallegos, M. A., Mendiola, R. C., Aparicio, A. R. J., & Ocampo, M. L. A. (2014). Prebiotic potential of Agave angustifolia Haw fructans with different degrees of polymerization. Molecules, 19(8), 12660-12675. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6271457/

- Kris-Etherton, Penny & Hecker, Kai & Shaffer Taylor, Denise & Zhao, Guixiang & Coval,Stacie & Binkoski, Amy Chapter 18 - Dietary Macronutrients and Cardiovascular Risk, Editor(s): Ann M. Coulston, Cheryl L. Rock, Elaine R. Monsen, Nutrition in the Prevention and Treatment of Disease, Academic Press, 2001, Pages 279-290, ISBN 9780121931551, https://doi.org/10.1016/B978-012193155-1/50020-9.

- López, Mercedes G. & Mancilla-Margalli, N.A.. (2007). The nature of fructooligosaccharides in agave plants. Recent Adv. Fructooligosaccharides Res.. 47-67. https://www.researchgate.net/publication/286685949_The_nature_of_fructooligosaccharides_in_agave_plants

- López, Mercedes G. & Mancilla-Margalli, Norma & Mendoza Díaz, Guillermo. (2004). Molecular Structures of Fructans from Agave tequilana Weber var. azul. Journal of agricultural and food chemistry. 51. 7835-40. 10.1021/jf030383v. www.researchgate.net/publication/8947337_Molecular_Structures_of_Fructans_from_Agave_tequilana_Weber_var_azul