Vodka

Vodka is misunderstood. In the United States, it has been downed as a shot, and used as a bittering agent to tone back highly sugary drinks. It is partially because of this approach to consumption that vodka had become “as smooth as possible” and “without distinctive character, aroma, taste or color”. However, this misses the intricacies and nuance of vodka. To appreciate this spirit, one only needs to look at the traditional food pairings in vodka’s home, the Baltic Region of Europe. There, traditional methods of sipping vodka neat while having appetizers of cured meat and pickled food include vodka with the zakuski in Russia, the smörgåsbord in Sweden, the koldtbord in Norway, the kolde bord in Denmark, and the seisova pöytä in Finland.

What makes one vodka analytically different from another is less definitive than it is with other spirits. Though base fermentables, distillation method, and production process are points of differentiation, they are relatively straightforward and the quantifiable results of those processes are less definitive. This is because vodka comes off the still at 96% Ethanol Alcohol by Volume, and it is the remaining 4% being what differentiates one vodka from another. This can be compared to whiskey, another grain distillate, which comes off the still between 40-80% ABV. However, there has been research that corroborates differences in ingredients and production process, with the most insightful technique being solid-phase micro extraction with gas chromatography and mass spectrometric detection, which has been cited as most helpful in the determination of the variation in volatile aromatic compounds.

It is important to note that there are two schools of thought to the creation of vodka: purity of ethanol vs the traditional approach of maintaining a perceptible taste of grain or potato, which distinguishes vodka from an entirely neutral spirit. ” This is accomplished by leaving in particular aromatic compounds. As to which one is preferred is a matter of personal preference.

What makes one vodka analytically different from another is less definitive than it is with other spirits. Though base fermentables, distillation method, and production process are points of differentiation, they are relatively straightforward and the quantifiable results of those processes are less definitive. This is because vodka comes off the still at 96% Ethanol Alcohol by Volume, and it is the remaining 4% being what differentiates one vodka from another. This can be compared to whiskey, another grain distillate, which comes off the still between 40-80% ABV. However, there has been research that corroborates differences in ingredients and production process, with the most insightful technique being solid-phase micro extraction with gas chromatography and mass spectrometric detection, which has been cited as most helpful in the determination of the variation in volatile aromatic compounds.

It is important to note that there are two schools of thought to the creation of vodka: purity of ethanol vs the traditional approach of maintaining a perceptible taste of grain or potato, which distinguishes vodka from an entirely neutral spirit. ” This is accomplished by leaving in particular aromatic compounds. As to which one is preferred is a matter of personal preference.

Vodka Laws

A recent (2019) TTB rule change, reflects how vodka has always been produced, as well as reflects the shift in craft distilling which places an emphasis on flavor. However, unlike other products which have more distinct delineations in flavor, vodka’s flavor differences are more subtle due to the high proof at which it comes off the still. These subtle differences do have common trends, largely due to the base fermentable that they are made from, as many of the other production techniques have minimal impact or are difficult to quantify.

-

United States

-

European Union

<

>

United States

Electronic Code of Federal Regulations Title 27, Chapter I, Subchapter A, Part 5, Subpart C §5.22 The standards of identity.

“Standards of identity for the several classes and types of distilled spirits set forth in this section shall be as follows (see also §5.35, class and type):

(a) Class 1; neutral spirits or alcohol. “Neutral spirits” or “alcohol” are distilled spirits produced from any material at or above 190° proof, and, if bottled, bottled at not less than 80° proof.

(1) “Vodka” is neutral spirits which may be treated with up to two grams per liter of sugar and up to one gram per liter of citric acid. Products to be labeled as vodka may not be aged or stored in wood barrels at any time except when stored in paraffin-lined wood barrels and labeled as bottled in bond pursuant to §5.42(b)(3). Vodka treated and filtered with not less than one ounce of activated carbon or activated charcoal per 100 wine gallons of spirits may be labeled as “charcoal filtered.””

Electronic Code of Federal Regulations Title 27, Chapter I, Subchapter A, Part 5, Subpart C §5.22 The standards of identity.

“Standards of identity for the several classes and types of distilled spirits set forth in this section shall be as follows (see also §5.35, class and type):

(a) Class 1; neutral spirits or alcohol. “Neutral spirits” or “alcohol” are distilled spirits produced from any material at or above 190° proof, and, if bottled, bottled at not less than 80° proof.

(1) “Vodka” is neutral spirits which may be treated with up to two grams per liter of sugar and up to one gram per liter of citric acid. Products to be labeled as vodka may not be aged or stored in wood barrels at any time except when stored in paraffin-lined wood barrels and labeled as bottled in bond pursuant to §5.42(b)(3). Vodka treated and filtered with not less than one ounce of activated carbon or activated charcoal per 100 wine gallons of spirits may be labeled as “charcoal filtered.””

The European Union

REGULATION (EC) No 110/2008 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL ANNEX II

15. Vodka

(a) Vodka is a spirit drink produced from ethyl alcohol of agricultural origin obtained following fermentation with yeast from either:

(i) potatoes and/or cereals, or

(ii) other agricultural raw materials, distilled and/or rectified so that the organoleptic characteristics of the raw materials used and by-products formed in fermentation are selectively reduced.

This process may be followed by redistillation and/or treatment with appropriate processing aids, including treatment with activated charcoal, to give it special organoleptic characteristics.

Maximum levels of residue for ethyl alcohol of agricultural origin shall meet those laid down in Annex I, except that the methanol content shall not exceed 10 grams per hectolitre of 100 % vol. alcohol.

(b)

The minimum alcoholic strength by volume of vodka shall be 37.5 %.

(c)

The only flavourings which may be added are natural flavouring compounds present in distillate obtained from the fermented raw materials. In addition, the product may be given special organoleptic characteristics, other than a predominant flavour.

(d)

The description, presentation or labelling of vodka not produced exclusively from the raw material(s) listed in paragraph (a)(i) shall bear the indication ‘produced from ...’, supplemented by the name of the raw material(s) used to produce the ethyl alcohol of agricultural origin. Labelling shall be in accordance with Article 13(2) of Directive 2000/13/EC.

REGULATION (EC) No 110/2008 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL ANNEX II

15. Vodka

(a) Vodka is a spirit drink produced from ethyl alcohol of agricultural origin obtained following fermentation with yeast from either:

(i) potatoes and/or cereals, or

(ii) other agricultural raw materials, distilled and/or rectified so that the organoleptic characteristics of the raw materials used and by-products formed in fermentation are selectively reduced.

This process may be followed by redistillation and/or treatment with appropriate processing aids, including treatment with activated charcoal, to give it special organoleptic characteristics.

Maximum levels of residue for ethyl alcohol of agricultural origin shall meet those laid down in Annex I, except that the methanol content shall not exceed 10 grams per hectolitre of 100 % vol. alcohol.

(b)

The minimum alcoholic strength by volume of vodka shall be 37.5 %.

(c)

The only flavourings which may be added are natural flavouring compounds present in distillate obtained from the fermented raw materials. In addition, the product may be given special organoleptic characteristics, other than a predominant flavour.

(d)

The description, presentation or labelling of vodka not produced exclusively from the raw material(s) listed in paragraph (a)(i) shall bear the indication ‘produced from ...’, supplemented by the name of the raw material(s) used to produce the ethyl alcohol of agricultural origin. Labelling shall be in accordance with Article 13(2) of Directive 2000/13/EC.

Protected Geographical Indication

-

Estonian Vodka

-

Vodka of Finland

-

Swedish Vodka

-

Norwegian Vodka

-

Polish Vodka

<

>

Estonian Vodka

PGI-EE-01971: https://www.dfat.gov.au/sites/default/files/28s.docx

Ingredients

Produced from grain of rye or wheat and/or potatoes produced in the Republic of Estonia. Soft Estonian water which meets Estonian drinking water requirements must be used during sweetening, fermentation and distillation. The Estonian soft water may be further softened through reverse osmosis and should contain a chemical composition of 90 mg/l (±10 %) of calcium (Ca) and 20 mg/l (±10 %) of magnesium (Mg). If the water does not meet the requirements as regards Ca and Mg, it is strongly recommended that it should be brought into conformity. Additionally distilled water may not be used in the blending of vodka.

The only additives that may be used are organic flavoring compounds made using local grain and/or potatoes. It is prohibited to add any artificial substances or sugar.

Production Regions

Production Process

Bottle Proof: Minimum ABV 40 %.

PGI-EE-01971: https://www.dfat.gov.au/sites/default/files/28s.docx

Ingredients

Produced from grain of rye or wheat and/or potatoes produced in the Republic of Estonia. Soft Estonian water which meets Estonian drinking water requirements must be used during sweetening, fermentation and distillation. The Estonian soft water may be further softened through reverse osmosis and should contain a chemical composition of 90 mg/l (±10 %) of calcium (Ca) and 20 mg/l (±10 %) of magnesium (Mg). If the water does not meet the requirements as regards Ca and Mg, it is strongly recommended that it should be brought into conformity. Additionally distilled water may not be used in the blending of vodka.

The only additives that may be used are organic flavoring compounds made using local grain and/or potatoes. It is prohibited to add any artificial substances or sugar.

Production Regions

- Fermentation and Distillation must occur in the Republic of Estonia

- There are no geographical restrictions on the packaging

Production Process

- Rye or wheat is kibbled to wholegrain consistency using the traditional method of dry milling in which 25 % of the flour must consist of particles measuring more than 1 mm. That means that the grain must not be de-husked, polished or processed.

- Potatoes are washed and crushed without peeling.

- The mashing of potatoes or cereals takes place at a temperature of 55-57 C, after which the mash is thermally processed at between 80-90 C, during which it must be ensured that the mash does not come to the boil. This is followed by the sweetening of the mash at 55-57 C; green malt, malted cereals or other natural enzymes are added to the mash. From there, the mash is transported to fermentation vats, where the yeast is added. The fermentation process takes about 72 hours.

- The fermented mash is then transported to the distillation stage.

- Minimum distillation strength: 96.0% ABV.

- Filtration: May undergo additional filtration.

Bottle Proof: Minimum ABV 40 %.

Suomalainen Vodka / Finsk Vodka / Vodka of Finland

(PGI-FI-02040)

Insight from the Technical File: www.dfat.gov.au/sites/default/files/30s.docx

Ingredients

Typically based on barley (more than 95% produced from barley), which is hardly used in other parts of the world. It may also be produced from potatoes. The raw materials of the vodka, with the exception of sweeteners, must be Finnish.

Groundwater or spring water so clean that no further chemical processing is necessary is used in the dilution process. The authenticity of Vodka of Finland may be identified on the basis of the water it contains.

The product may not be dyed, and flavoring is authorized only with natural flavoring agents obtained from the fermentation of the raw materials. In addition, certain organoleptic characteristics other than the predominant taste may be given to the product.

Production Region

Production Process

Other Chemical Requirements:

Methanol content is less than 2 g/hl.

Bottling Proof: 37.5% - 60% ABV.

(PGI-FI-02040)

Insight from the Technical File: www.dfat.gov.au/sites/default/files/30s.docx

Ingredients

Typically based on barley (more than 95% produced from barley), which is hardly used in other parts of the world. It may also be produced from potatoes. The raw materials of the vodka, with the exception of sweeteners, must be Finnish.

Groundwater or spring water so clean that no further chemical processing is necessary is used in the dilution process. The authenticity of Vodka of Finland may be identified on the basis of the water it contains.

The product may not be dyed, and flavoring is authorized only with natural flavoring agents obtained from the fermentation of the raw materials. In addition, certain organoleptic characteristics other than the predominant taste may be given to the product.

Production Region

- Distillation, rectification, blending and the adding of any flavorings must be done in Finland.

- The product may be bottled outside the geographical area.

Production Process

- The milled barley is elutriated using water, and the mashing process converts the barley flour into sugar. Similarly other permissible grains may undergo the same process. The sugary mash is then pumped into the continuous fermentation process to feed the yeast.

- The fermented mash is added to the continuous distillation process, where several columns are used to produce neutral ethanol. The first columns separate the dregs from the water and enrich the raw ethanol. After this other columns distil and separate (rectify) most of the impurities and concentrate the ethanol nearly to its final strength. The last column purifies the final product and creates the typical neutral profile. Batch distillation may also be used.

Other Chemical Requirements:

Methanol content is less than 2 g/hl.

Bottling Proof: 37.5% - 60% ABV.

Svensk Vodka / Swedish Vodka

(PGI-SE-01926)

https://ec.europa.eu/geographical-indications-register/eambrosia-public-api/api/v1/attachments/66175

Ingredients

Must be produced from wheat, rye, barley, oat or potatoes cultivated in Sweden. Groundwater may come from eskers created by the inland ice. Water must be of Swedish origin and comply with Swedish regulations on drinking water. Additionally, chlorination is limited. Svensk Vodka is usually unsweetened, but sucrose may be added at a maximum level of 2 grams per litre in order to round off the taste.

Production Region

The rectification and the blending with water must take place in Sweden. The water used must be of Swedish origin.

Production Process

Chemical Requirements

Bottling Proof: 40% - 60% ABV

(PGI-SE-01926)

https://ec.europa.eu/geographical-indications-register/eambrosia-public-api/api/v1/attachments/66175

Ingredients

Must be produced from wheat, rye, barley, oat or potatoes cultivated in Sweden. Groundwater may come from eskers created by the inland ice. Water must be of Swedish origin and comply with Swedish regulations on drinking water. Additionally, chlorination is limited. Svensk Vodka is usually unsweetened, but sucrose may be added at a maximum level of 2 grams per litre in order to round off the taste.

Production Region

The rectification and the blending with water must take place in Sweden. The water used must be of Swedish origin.

Production Process

- May be distilled in pot stills or using columns

- In the first stage of distillation, the ethanol formed during fermentation is separated from the mash in a stripping column

- In a second stage, the ethanol is concentrated in a raw spirit column. The resulting raw spirit, which has an ethanol content of 80-90% ABV and also contains volatile substances, fusel oils and heavier fractions, is then distilled continuously in several separate columns, where each column consists of a large number of trays, so that these unwanted impurities can be separated and removed in a controlled manner.

- In continuous distillation, the process is usually configured with an extraction column, a rectification stage and a methanol column in order to reach a final ethanol strength of 96% ABV.

- A special feature of the manufacturing process is to add some flavour from the raw material to the vodka after distillation in order to endow it with the raw material’s character.

Chemical Requirements

- Slight but perceptible taste of grain or potato, which distinguishes it from an entirely neutral spirit.

- Dry matter content of 1.0 gram per hectolitre and a maximum methanol content of 5 grams per hectolitre of alcohol (100 per cent by volume).

Bottling Proof: 40% - 60% ABV

Norsk Vodka / Norwegian Vodka

PGI-NO-02240: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.C_.2019.241.01.0011.01.ENG&toc=OJ:C:2019:241:TOC

Ingredients

Production Region

Production Process

Bottle proof: 37.5 % ABV to 60.0 % ABV.

PGI-NO-02240: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.C_.2019.241.01.0011.01.ENG&toc=OJ:C:2019:241:TOC

Ingredients

- Produced from potatoes or grains ( it is not specified in the technical file if the fermentables must be from Norway)

- Added sugar up to a maximum dry content of 1 g per litre in order to soften it.

Production Region

- Dilution with water in the post-distillation processing and bottling may take place outside of the Kingdom of Norway.

- Potatoes or grains must be fermented and distilled in Norway

Production Process

- Distillation occurs in batches or is continuously distilled using a column still

- Distillation ABV: At lest 96.0 % ABV

- Other chemical requirements:

- Contains no more than 3 g methanol per hectolitre of 100 % ethanol

Bottle proof: 37.5 % ABV to 60.0 % ABV.

Polska Wódka / Polish Vodka

Technical File: www.dfat.gov.au/sites/default/files/187s.docx

Ingredients

Production Region

All stages in its production take place in Poland and it may be aged with a view to imparting specific organoleptic properties.

Production Process

Other Chemical Requirements

Technical File: www.dfat.gov.au/sites/default/files/187s.docx

Ingredients

- Any combination of spring or winter cereals of rye, wheat, barley, oats, triticale grown in Poland

- Or exclusively from potatoes of ware or starch-rich varieties grown in Poland;

- Vodka may not contain any additives other than water

- The water used must be of potable water quality in keeping with current statutory requirements. It is recommended that water from deep wells be used. Water for the production of Polska Wódka/Polish Vodka is also treated using a demineralisation process.

- Has a dominant flavor other than that of the raw materials used in its production, containing natural flavorings and, in certain cases, colorings.

- Has a maximum sugar content, expressed as invert sugar, depends on the alcohol content; it is: 37.5 g/l for vodka having an alcoholic strength of 37.5 % vol to 40 g/l for vodka having an alcoholic strength of 40 % vol., etc.

Production Region

All stages in its production take place in Poland and it may be aged with a view to imparting specific organoleptic properties.

Production Process

- The cereal grains or potatoes are washed to remove dirt and any contaminants. The starch is then released by means of high-pressure cooking or using physical methods without heating.

- The next stage is the hydrolysis of starch into fermentation sugars. After cooling, the saccharified mash is fermented in a fermentation tank. Distillery yeast is added at this stage. The fermentation process lasts for 2-3 days on average and produces ethanol, fermentation by-products such as aldehydes, esters and fusels, and fermentation gases (CO2).

- The fermented mash is distilled in distillation columns or pot stills.

- Distillation produces a raw distillate of agricultural origin which has the following parameters: Organoleptic characteristics: no detectable taste other than that of ethanol and the fermented raw material;

- Minimum alcoholic strength: 88.0 % vol.;

- Total acidity, expressed in grams of acetic acid per hectolitre of 100 % vol. alcohol: 8.0;

- Aldehydes expressed in grams of acetaldehyde per hectolitre of 100 % vol. alcohol: 15;

- The distillate is filtered to impart clarity. The filtration media may not have a pore size greater than 1 µm.

- May be aged in order to impart particular organoleptic properties.

- May be stored for a defined period in suitable containers in order to stabilise and harmonise it.

- Flavoured vodka production

- The product may be made by flavouring ethyl alcohol of agricultural origin as specified above either by using natural flavourings such as distillates and macerates (extracts) obtained from plant materials. The plant raw materials most commonly used to produce Polska Wódka/Polish Vodka (flavoured vodka) are fruit such as sour cherries, apples, pears, currant fruit, quince and rowanberries, as well as spices and herbs. Foodstuffs such as juices or wine are also common.

- May be sweetened and/or coloured.

Other Chemical Requirements

- Maximum level of residues:

- Esters expressed in grams of ethyl acetate per hectolitre of 100 % vol. alcohol: 0.5;

- Acetaldehyde expressed in grams of per hectolitre of 100 % vol. alcohol: 0.3;

- Higher alcohols expressed in grams of methyl-2- propanol-1 per hectolitre of 100 % vol. alcohol: 0.3;

- Methanol expressed in grams per hectolitre of 100 % vol. alcohol: 10;

- Dry extract expressed in grams per hectolitre: 3.5;

- Furfural: not detectable.

- Bottling Proof: 37.5 % - 55 % ABV

- Bottling Proof of flavored vodka: 37.5% - 70 % ABV.

Ingredients

Though there is no scientific consensus on the impact of ingredients on the flavor of vodka, it is generally accepted by Hawai’i Beverage Guide that ingredients matter, based upon personal experience, informal discussions with the bar and distilling communities, and review of scientific literature. This position is supported by a 2017 literature review conducted by Dr. Matthew Pauley and Dr. Dawn Maskell of Heriot Watt University's International Centre for Brewing and Distilling who write, “It should be noted that there is no consensus of opinion on the importance of the contribution of the choice of yeast strain to the levels of metabolic by-products produced, although the authors of this review are of the opinion that common sense would suggest that both strain selection and raw material choice would have an influence on yeast growth, fermentation efficiency, and the production of flavour active by-products such as esters, aldehydes, and higher alcohols.”

-

Base Fermentable

-

Water

-

Yeast

-

Other Ingredients

<

>

It is generally accepted that the base fermentable has an impact on vodka, and that vodkas made from the same base fermentable are more alike than they are different from vodkas made from another base fermentable. The exception is if additives are added post distillation.

Chemistry of Fermentable Variation

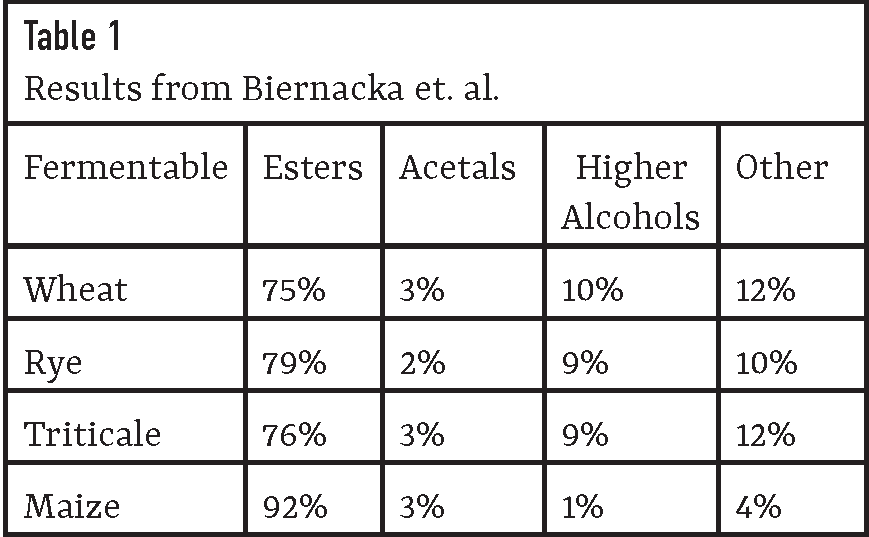

In the research done by Biernacka, P.; Wardencki, W. Volatile composition of raw spirits of different botanical origin. J. Inst. Brew.2012, 118, 393–400. https://onlinelibrary.wiley.com/doi/full/10.1002/jib.55

90% ABV raw spirit made from maze (corn), wheat, rye and Triticale (hybrid of wheat and rye) was analyzed. This study found that there were variations in the esters, acetals, higher alcohols and other volatile aroma compounds between the distillates, but did not specify the specific volatile aroma compounds in each category. The figures can be found on Table 1:

In the research done by Biernacka, P.; Wardencki, W. Volatile composition of raw spirits of different botanical origin. J. Inst. Brew.2012, 118, 393–400. https://onlinelibrary.wiley.com/doi/full/10.1002/jib.55

90% ABV raw spirit made from maze (corn), wheat, rye and Triticale (hybrid of wheat and rye) was analyzed. This study found that there were variations in the esters, acetals, higher alcohols and other volatile aroma compounds between the distillates, but did not specify the specific volatile aroma compounds in each category. The figures can be found on Table 1:

The presence of analytical variation is also noted by Pauley and Maskell (2017), who cited research by Klosowski, Czuprynski (2006) 2 and Ng, Hupé, Harnois, and Moccia (1996). Pauley and Maskell (2017) specified that Ng, et al. “determined that 18 different vodkas could be differentiated according to the raw materials used and the method of production. They noted that ethyl ester levels (fermentation by-products from yeast) were one of the markers used to identify the different spirits.” Please note that Hawaii Beverage Guide was not able to access these studies in their entirety, and therefore have no insight into the materials and methods used.

Typical Base Fermentable Characteristics

The characteristics of vodka often mirror a bread made from the same ingredients, with a butter like quality to them. This should come as no surprise as both vodka and bread are made from yeast and grain.

The characteristics of vodka often mirror a bread made from the same ingredients, with a butter like quality to them. This should come as no surprise as both vodka and bread are made from yeast and grain.

Bulk Alcohol Refined

Major Producers of Bulk Spirits

Domestic Vodka/Gin Bases

All Spirits are GMO Free, Kosher, Gluten/Allergen Free

Imported Vodka/Gin Neutral Bases

- Some vodka is made from purchasing Bulk Neutral Grain Spirit (GNS) and then add their own distillate to it, or refine and modify the bulk spirit though additional distillation, filtration and additives.

- The following is an example Neutral Bases available from UltraPure

https://ultrapure-usa.com/services-2/distilleries-blenders-bottlers/#

Major Producers of Bulk Spirits

- UltraPure: https://ultrapure-usa.com/services-2/spirits-brand-owners/

- MGP: https://www.mgpingredients.com/

Domestic Vodka/Gin Bases

All Spirits are GMO Free, Kosher, Gluten/Allergen Free

- Missouri Corn Alcohol: 190 proof, 6x distilled,

- Iowa Corn Alcohol: 190 proof, 4x distilled

- Illinois Corn Alcohol: 190 proof, 4x distilled

- Kansas Corn Alcohol: 190 proof, 4x distilled

- Organic Corn Alcohol: 190 proof, USDA Certified Organic

- Neutral Sugar Cane Alcohol: 190 proof, 4x distilled

Imported Vodka/Gin Neutral Bases

- French Wheat Alcohol: 4x distilled in the Champagne Valley of France

- Amsterdam Dutch Wheat Alcohol: 4x Distilled

- Polish Potato Alcohol; 5x distilled from premium Polish potato varieties, Kosher

- Organic Northern Italian Wheat; 4x distilled from Italian grown wheat, USDA/NOP Certified Organic, Kosher

- Wheat Grain Neutral Spirits; 190 proof, distilled from 100% wheat

- Organic Neutral Sugar Cane: USDA/NOP and EU Certified Organic, Non-GMO, Kosher

- Neutral Rye Alcohol: 5x distilled

- Neutral Grape Alcohol: 192 Proof, distilled from many French Grape varieties

Water

As vodka is 60% water, water chemistry will alter the chemical profile of the final distillate. Though not providing aroma compounds, water typically contains salts which do affect the ionic composition of the vodka, to the extent that the ionic profile can be used to fingerprint a vodka.

Some distillers will track the pH of the proofing water because it is so important. Additionally, the ionic content (salts in water) can impact on taste. This is the reason why bottled water may have sulfate, potassium chloride, calcium chloride, sodium bicarbonate, and magnesium sulfate listed as ingredients alongside purified water on the Nutrition Facts label.

Though variations in water clearly impact the final flavor of the vodka, comparing the variations between different water sources does not provide a particularly helpful reference to how one vodka will quantifiably taste different from another. Rather, it can only be used to say that two vodkas will qualitatively differ in taste.

As vodka is 60% water, water chemistry will alter the chemical profile of the final distillate. Though not providing aroma compounds, water typically contains salts which do affect the ionic composition of the vodka, to the extent that the ionic profile can be used to fingerprint a vodka.

Some distillers will track the pH of the proofing water because it is so important. Additionally, the ionic content (salts in water) can impact on taste. This is the reason why bottled water may have sulfate, potassium chloride, calcium chloride, sodium bicarbonate, and magnesium sulfate listed as ingredients alongside purified water on the Nutrition Facts label.

Though variations in water clearly impact the final flavor of the vodka, comparing the variations between different water sources does not provide a particularly helpful reference to how one vodka will quantifiably taste different from another. Rather, it can only be used to say that two vodkas will qualitatively differ in taste.

Compared to other fermentations that use a combination of different yeast and bacterial varieties, saccharomyces cerevisiae is the most critical to the final distillate, as it produces the most ethanol and fewest non-ethanol volatile compounds. This can be contrasted with the fermentation of other spirits in which fermentation by bacteria like lactobacillus and other yeast strains such as schizosaccharomyces pombe are also important.

Pauley and Maskell (2017) noted that yeast strain probability does have an impact, and cited work by Klosowsk, Czupryński, and Wolska (2006) which found that aldehydes and higher alcohols were influenced by yeast strain selection. Another study by Klosowsk and Czupryński (2006) suggested that no statistical differences could be determined between the two strains of the yeast examined, and that the differences in fermentation by-products in the final spirit were narrowed down to the raw material used. However, there was no indication that either study resulted in specific organoleptic differences attributed to each yeast, and Hawaii Beverage Guide did not have access to the full version of either study to assess the specific methods or results of the study.

It is Hawai’i Beverage Guide’s opinion that, though fermentation techniques matter in the production of vodka, using pH or yeast strain to compare how fermentation impacts different brands in regards to the final flavors of the vodka is inconclusive. This is because the resulting non-ethanol aroma compounds in the final distillate are minuscule compared to other spirits.

Pauley and Maskell (2017) noted that yeast strain probability does have an impact, and cited work by Klosowsk, Czupryński, and Wolska (2006) which found that aldehydes and higher alcohols were influenced by yeast strain selection. Another study by Klosowsk and Czupryński (2006) suggested that no statistical differences could be determined between the two strains of the yeast examined, and that the differences in fermentation by-products in the final spirit were narrowed down to the raw material used. However, there was no indication that either study resulted in specific organoleptic differences attributed to each yeast, and Hawaii Beverage Guide did not have access to the full version of either study to assess the specific methods or results of the study.

It is Hawai’i Beverage Guide’s opinion that, though fermentation techniques matter in the production of vodka, using pH or yeast strain to compare how fermentation impacts different brands in regards to the final flavors of the vodka is inconclusive. This is because the resulting non-ethanol aroma compounds in the final distillate are minuscule compared to other spirits.

Additives

- Sugar and citric acid may be added to alter the mouthfeel and texture of vodka.

Distillation

In the distillation of vodka, with the exception of batch distillation (pot stills with or without a reflux column), the number of times a vodka is distilled in continuous distillation is a commercial expression that alludes to the fact that a Coffey Still may be broken up into shorter columns to reduce the overall height necessary for distillation. For more insight into distillation, read Hawai'i Beverage Guides’ A Guide to Distillation in the June 2021 Issue or at hawaiibevguide.com/spirits.

What really matters in vodka distillation is reflux ratio. As discussed in our Guide to Distillation, reflux ratio is the ratio of the liquid that has returned to the distillation column to the amount of liquid removed. This matters because the higher the reflux ratio, the more purified the distillate, as reflux is what helps to separate out the various volatile/aroma compounds in the azeotropic solution. Given that vodka must be distilled over 95% ABV, and that there is a theoretical maximum distillation proof of 95.57% ABV, heads, hearts, and tails “cuts” are not particularly possible with vodka, unlike other distillates which can vary significantly depending on the distiller. Additionally, insight into what non-ethanol volatile aroma compounds remain in the final distillate due to different production methodologies could not be found by Hawai'i Beverage Guide and, unfortunately, reflux ratio is not currently a metric maintained on-hand by most distillers. What can generalized, however, is that:

What really matters in vodka distillation is reflux ratio. As discussed in our Guide to Distillation, reflux ratio is the ratio of the liquid that has returned to the distillation column to the amount of liquid removed. This matters because the higher the reflux ratio, the more purified the distillate, as reflux is what helps to separate out the various volatile/aroma compounds in the azeotropic solution. Given that vodka must be distilled over 95% ABV, and that there is a theoretical maximum distillation proof of 95.57% ABV, heads, hearts, and tails “cuts” are not particularly possible with vodka, unlike other distillates which can vary significantly depending on the distiller. Additionally, insight into what non-ethanol volatile aroma compounds remain in the final distillate due to different production methodologies could not be found by Hawai'i Beverage Guide and, unfortunately, reflux ratio is not currently a metric maintained on-hand by most distillers. What can generalized, however, is that:

- Pot still vodka has the lowest reflux ratio of any still type

- Pot still with a reflux column has an intermediate amount of reflux

- Continuous distillation has the most reflux

|

Distillation

|

Filtration

- Vodka does not need to be filtered. Vodka is already coming off the still at a very high proof, therefore it by definition has already removed most of the non-ethanol components.

-

Activated Carbon

-

Common Filtration

-

Ozone Filtration

-

Not Filtration

<

>

Activated carbon or activated charcoal is the most common type of filtration medium used in the production of vodka.

Process

During this process, activated carbon removes “organic admixtures from the ethanol solution and ensure the catalysis of a number of chemical reactions (oxidation, esterification, isomerisation, hydration, etc.)”.8 This is possible because “activated carbon has a large surface area, and consist of macropores (>25 nm), mesopores (1 nm < D < 25 nm), and micropores (<1 nm) and that most volatile byproducts of fermentation, such as higher alcohols, cyclic compounds, and ethers, have higher absorbability on activated charcoal".9 It should be noted that acetaldehyde, which can be described as having a tart flavor reminiscent of green apples, is not easily filtered by activated charcoal. Additionally, not all activated carbon filtration is the same, as the type of activated carbon, the amount of activated carbon, and the duration of exposure of the distillate to activated carbon all impact its efficacy.

- Typically, the charcoal made from pine, birch, poplar or oak.

Process

During this process, activated carbon removes “organic admixtures from the ethanol solution and ensure the catalysis of a number of chemical reactions (oxidation, esterification, isomerisation, hydration, etc.)”.8 This is possible because “activated carbon has a large surface area, and consist of macropores (>25 nm), mesopores (1 nm < D < 25 nm), and micropores (<1 nm) and that most volatile byproducts of fermentation, such as higher alcohols, cyclic compounds, and ethers, have higher absorbability on activated charcoal".9 It should be noted that acetaldehyde, which can be described as having a tart flavor reminiscent of green apples, is not easily filtered by activated charcoal. Additionally, not all activated carbon filtration is the same, as the type of activated carbon, the amount of activated carbon, and the duration of exposure of the distillate to activated carbon all impact its efficacy.

Filtration

- Filtration is a matter of preference, and marketing material.

- Paper filters are sometimes used. Their effectiveness is debatable, as though they are used as sediment filters in barrel aged products, there should be no sediment from the distillate or the water used for proofing unless the equipment was dirty.

- Chill filtration may also be used. This method is when the temperature of a liquid is lowered so that certain long-chain molecules coagulate, which makes these molecules easier to remove.

Ozone (03) may also be used to purify ethanol. 10 A study by Cai et al., based on an earlier study by Onuki et al.,11 showed that of the ten common congeners tested (acetaldehyde, ethyl vinyl ether, 1,1-diethoxyethane, isoamyl alcohol, isoamyl acetate, styrene, 2-pentylfuran, ethyl hexanoate, ethyl octanoate and ethyl decanoate), the 03 process, when combined with others, yielded the following:

A study by Cai et al., based on an earlier study by Onuki et al.,11 showed that of the ten common congeners tested (acetaldehyde, ethyl vinyl ether, 1,1-diethoxyethane, isoamyl alcohol, isoamyl acetate, styrene, 2-pentylfuran, ethyl hexanoate, ethyl octanoate and ethyl decanoate), the 03 process, when combined with others, yielded the following:

- Ozone treatment of 40 mg/L resulted in a > 56% and a >36% removal of styrene and 2-pentylfuran, respectively, without significant generation of byproducts.

- Granular activated carbon of 55 g/L and 270 min adsorption time resulted in 84, >72 and >78% removals of ethyl hexanoate, ethyl octanoate and ethyl decanoate, respectively.

- CO2-based stripping, at 675 LStripping gas/LSample, removed 65, >82 and >83% acetaldehyde, ethyl vinyl ether and 1,1-diethoxyethane, respectively. Ozone (03) may also be used to purify ethanol. 10

A study by Cai et al., based on an earlier study by Onuki et al.,11 showed that of the ten common congeners tested (acetaldehyde, ethyl vinyl ether, 1,1-diethoxyethane, isoamyl alcohol, isoamyl acetate, styrene, 2-pentylfuran, ethyl hexanoate, ethyl octanoate and ethyl decanoate), the 03 process, when combined with others, yielded the following:

- Ozone treatment of 40 mg/L resulted in a > 56% and a >36% removal of styrene and 2-pentylfuran, respectively, without significant generation of byproducts.

- Granular activated carbon of 55 g/L and 270 min adsorption time resulted in 84, >72 and >78% removals of ethyl hexanoate, ethyl octanoate and ethyl decanoate, respectively.

- CO2-based stripping, at 675 LStripping gas/LSample, removed 65, >82 and >83% acetaldehyde, ethyl vinyl ether and 1,1-diethoxyethane, respectively.

“Filtering” with rocks and other mineral sources post distillation is incorrect terminology, as most are too porous to capture the small volatile compounds. Rather ethanol may dissolve these minerals into the distillate, making them additives. For more see the following section: “Additives - Minerals”.

Other non-reactive and inert materials including quartz or metals like gold are occasionally used. Their effectiveness differs, due to the chemical composition and structure. For example, if diamonds which are non-porous and non-reactive are used, then essentially nothing happens.

Ultimately it is in Hawaii Beverage Guide’s opinion that the filtration methodology matters, however there are too many variables to be able to conclusively say what specific organoleptic changes will be caused by a specific filtration methodology.

Other non-reactive and inert materials including quartz or metals like gold are occasionally used. Their effectiveness differs, due to the chemical composition and structure. For example, if diamonds which are non-porous and non-reactive are used, then essentially nothing happens.

Ultimately it is in Hawaii Beverage Guide’s opinion that the filtration methodology matters, however there are too many variables to be able to conclusively say what specific organoleptic changes will be caused by a specific filtration methodology.

Additives

Common additives to vodka include:

- NaHCO3 (Sodium bicarbonate), which makes vodka more alkaline.

- HCl (hydrochloric acid), which makes vodka more neutral and can enhance the softness of taste.

- Honey or sugar, which were traditional ways to increase mouthfeel.

- Glycerin and citric acid are additional options. In 1956, Revenue Ruling 56-98, 1956-1 C.B. 811, concluded that citric acid and sugar were not considered to be flavoring ingredients which would materially affect the taste of vodka or change its basic character so long as the sugar did not exceed two-tenths of 1 percent and citric acid was only added in a "trace amount." The ruling did not quantify "trace amount." Nevertheless, it is clear that citric acid usage was intended as a smoothing agent to correct objectionable tastes which might result from such things as the water used in reducing the proof, the charcoal used in distillation, or the glass in which packaged. Available information indicates that the use of citric acid from this time until the 1980's was in the range of approximately 49 to 150 parts per million (ppm). However, starting in the 1980's, the quantity of citric acid added to vodka increased significantly. However, upon additional study in 1995,a "trace amount" of citric acid within the meaning of 27 C.F.R. 5.23(a) (3) shall be no more than 1,000 ppm."12

- Minerals commonly found in water including calcium and phosphorus may be added to vodka by running the distillate over rocks and other inorganic mineral sources. This occurs because many minerals are soluble in ethanol. 13

The Flavor of Vodka

-

Chemical Structure

-

Aroma Compounds

<

>

A study by Hu et. al. suggested that variations in mouthfeel can be attributed to differences in the number of water molecules that can be arranged around ethanol in a cage-like structure called a hydrate. Though E (5.3+/- .01) H2O water molecules per one ethanol molecule is most common, this number can vary between brands. From this insight, the researchers hypothesized that vodka with a higher amount of water clusters would result in a watery mouthfeel. Conversely, a highly structured vodka with the presence of ethanol-only clusters would have a less watery mouthfeel. How variations in ethanol clusters are intentionally created was not suggested by the study.

For a more thorough discussion on the chemical analysis of vodka chemistry, we recommend reading the following literature review:

Wiśniewska, P., Śliwińska, M., Dymerski, T. et al. The Analysis of Vodka: A Review Paper. Food Anal. Methods 8, 2000–2010 (2015). https://doi.org/10.1007/s12161-015-0089-7

https://link.springer.com/article/10.1007/s12161-015-0089-7

* The data is somewhat conflicting, as countries have varying degrees of control over their producers and different regulations, and many of the studies cited may consist entirely of products not found in U.S. markets

Wiśniewska, P., Śliwińska, M., Dymerski, T. et al. The Analysis of Vodka: A Review Paper. Food Anal. Methods 8, 2000–2010 (2015). https://doi.org/10.1007/s12161-015-0089-7

https://link.springer.com/article/10.1007/s12161-015-0089-7

* The data is somewhat conflicting, as countries have varying degrees of control over their producers and different regulations, and many of the studies cited may consist entirely of products not found in U.S. markets

Regions and Styles

- Regions often dictate style

- Eastern European countries like Poland and Ukraine make robust flavorful vodka

- Scandinavian Countries produce more neutral styles of vodka

- Americans do a little bit of everything, however, most of the corn based vodka comes from the United States, and due to the desire of the American consumer for a “smooth” product for shot consumption, they tend to have less flavor.

- Polish Vodka tends to be made from potatoes

- French Vodka tends to use wheat

Vodka and Food Pairing

Furthermore from a cultural perspective, we would encourage exploration of pairing vodka from Europe with the foods they were traditionally paired with, and promote this cultural thought exchange, as food and beverage pairings in Europe are much bigger than pairing wine with food as found in France and Italy.

For a more modern take on menu execution with .5 oz tasters of vodka:

- Russian Caviar or Vegetables with Sour Cream Dip - Russian Style Vodka

- pickled herring (sill) with Swedish VodkaSweedish Gravlax with Scandinavian Vodka

- Big Island Abalone with Hawaii Vodka

- French vodka and bri (or french friends)

Reference

- Vodka Distilled by Tony Abou-Ganim

Resources and Suggested Reading

1. Pauley, Matthew & Maskell, Dawn. (2017). Mini-Review: The Role of Saccharomyces cerevisiae in the Production of Gin and Vodka. Beverages. 3. 13. 10.3390/beverages3010013.

https://www.mdpi.com/2306-5710/3/1/13

2. Grzegorz, Kłosowski & Czupryński, Boguslaw. (2006). Kinetics of acetal and esters formation during alcoholic fermentation of various starchy raw materials with application of yeasts Saccharomyces cerevisiae. Journal of Food Engineering. 72. 242-246. 10.1016/j.jfoodeng.2004.12.001.

3. Ng, L.-K.; Hupé, J.; Harnois, J.; Moccia, D. Characterisation of commercial vodkas by solid-phase microextraction and gas chromatography/mass spectrometry analysis. J. Sci. Food Agric. 1996, 71, 380–388.

4. Klosowski,G.;Czupryński,B.;Wolska,M. Characteristics of alcoholic fermentation with the application of Saccharomyces cerevisiae yeasts: As-4 strain and I-7–43 fusant with amylolytic properties. J. Food Eng. 2006, 76, 500–505.

5. Klosowski,G.;Czupryński, B. Kinetics of acetals and esters formation during alcoholic fermentation of various starchy raw materials with application of yeasts Saccharomyces cerevisiae. J. Food. Eng. 2006, 72, 242–246.

6. Kolomiets, O., Lachenmeier, D., Hoffman, U., & Seisler, H. (2010). Quantitative determination of quality parameters and authentication of vodka using near infrared spectroscopy. Journal of Near Infrared Spectroscopy, 18(1), 59. https://doi.org/10.1255/JNIRS.866

7. Lachenmeier, D.W., Attig, R., Frank, W. et al. The use of ion chromatography to detect adulteration of vodka and rum. Eur Food Res Technol 218, 105–110 (2003). https://doi.org/10.1007/s00217-003-0799-8

https://www.ua-bw.de/uploaddoc/cvuaka/ionenchromatographie.pdf

8. Kyselová, Lucie & Přinosilová, Šárka & Riddellová, Kateřina & Hajšlová, Jana & Melzoch, Karel. (2012). Changes in Quality Parameters of Vodka Filtered through Activated Charcoal. Czech Journal of Food Sciences. 30. 10.17221/361/2011-CJFS.

https://www.researchgate.net/publication/268269931_Changes_in_Quality_Parameters_of_Vodka_Filtered_through_Activated_Charcoal

9. Onuki, Shinnosuke & Koziel, Jacek & Jenks, William & Cai, Lingshuang & Rice, Somchai & Van Leeuwen, Hans. (2015). Ethanol purification with ozonation, activated carbon adsorption, and gas stripping. Separation and Purification Technology. 151. 165-171. 10.1016/j.seppur.2015.07.026.

https://www.researchgate.net/publication/280102025_Ethanol_purification_with_ozonation_activated_carbon_adsorption_and_gas_stripping

10. Cai, Lingshuang & Rice, Somchai & Koziel, Jacek & Jenks, William & Van Leeuwen, Hans. (2016). Further Purification of Food-Grade Alcohol to Make a Congener-free Product. Journal- Institute of Brewing. 122. 84-92. 10.1002/jib.295.

11. Onuki, Shinnosuke & Koziel, Jacek & Jenks, William & Cai, Lingshuang & Rice, Somchai & Van Leeuwen, Hans. (2015). Ethanol purification with ozonation, activated carbon adsorption, and gas stripping. Separation and Purification Technology. 151. 165-171. 10.1016/j.seppur.2015.07.026.

12. Bureau of Alcohol, Tobacco and Firearms. Ruling 97-1, Dec. 1995, www.ttb.gov/images/pdfs/rulings/97-1.htm.

13. “White Phosphorus - Solubilities.” Edited by Wireless Information System for Emergency Responders, U.S. National Library of Medicine, National Institutes of Health, webwiser.nlm.nih.gov/WebWISER/substance?substanceId=323&identifier=White+Phosphorus&identifierType=alias&menuItemId=39&catId=44.

14. Hu, N., Wu, D., Cross, K., Burikov, S., Dolenko, T., Patsaeva, S., & Schaefer, D. W. (2010). Structurability: A Collective Measure of the Structural Differences in Vodkas. Journal of Agricultural and Food Chemistry, 58(12), 7394–7401. https://doi.org/10.1021/JF100609C

https://www.academia.edu/16297667/Structurability_A_Collective_Measure_of_the_Structural_Differences_in_Vodkas

Vodka Distilled by Tony Abou-Ganim

www.themodernmixologist.com/products/Vodka-Distilled--.html

A History of Vodka William Pkhlebkin

Pokhlebkin, W., Pokhlebkin, V. V., Похлебкин, В. В. (1992). A History of Vodka. United Kingdom: Verso Books.

Your browser does not support viewing this document. Click here to download the document.

RSS Feed

RSS Feed